Keeping an eye on the air/fuel (A/F) mixture is an essential function of the engine management system because it affects emissions, fuel economy and performance. A slightly rich fuel mixture makes more power but it also increases carbon monoxide (CO) emissions. A leaner mixture helps fuel economy, but if the A/F mixture is too lean the engine may misfire, lose power and spew unburned fuel into the exhaust.

Keeping an eye on the air/fuel (A/F) mixture is an essential function of the engine management system because it affects emissions, fuel economy and performance. A slightly rich fuel mixture makes more power but it also increases carbon monoxide (CO) emissions. A leaner mixture helps fuel economy, but if the A/F mixture is too lean the engine may misfire, lose power and spew unburned fuel into the exhaust.

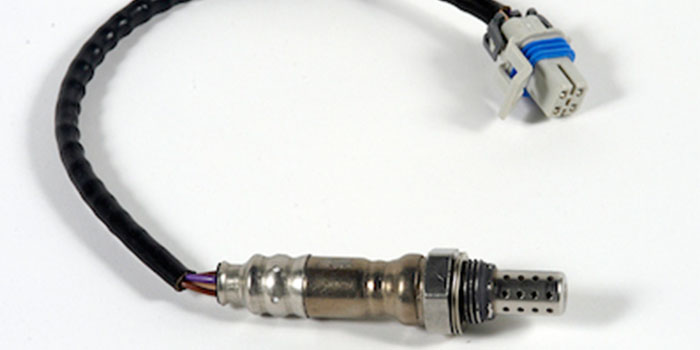

The key sensor that allows the engine computer to manage the A/F mixture is the oxygen (O2) sensor. The sensor is mounted in the exhaust manifold so it can read the oxygen contend of the exhaust. A high oxygen content indicates a lean mixture while a low oxygen content indicates a rich mixture.

First-generation O2 sensors function as a simple rich or lean indicator switch. When the A/F mixture is running rich, the O2 sensor generates a “high” voltage signal of 600 to 1000 millivolts, and when the A/F mixture is lean, the O2 sensor output signal drops to 300 millivolts or less.

When the engine computer sees a rich signal from the O2 sensor, it reduces the dwell (on time) of the fuel injectors when they are energized to lean the fuel mixture. Conversely, when the computer sees a lean signal from the O2 sensor, it richens the A/F mixture by increasing the dwell or on-time of the injector pulses. Thus, the feedback signal from the O2 sensor allows the engine computer to constantly fine tune the fuel mixture for the best power, fuel economy and emissions as operating conditions change.

Today’s second-generation “wideband” oxygen sensors (also called “Air/Fuel” sensors) are far more sophisticated. Instead of giving a simple high or low voltage signal to indicate a rich or lean fuel condition, a wideband O2 sensor or A/F sensor uses a variable voltage signal to indicate the exact air/fuel ratio. This allows much more precise control of the air/fuel mixture for better emissions, fuel economy and performance.

Oxygen sensors are engineered to last upwards of 100,000 miles, and most do last this long, as long as there are no other problems. Oil burning, combustion chamber coolant leaks (leaky head gasket or head cracks) or even using RTV sealer that contains a high level of silicone for a gasket repair may contaminate and ruin an oxygen sensor.

Oxygen sensors do age, and typically respond more slowly as the miles add up. Eventually, this may result in a loss of fuel economy, increase emissions and/or a Check Engine light with an oxygen sensor related code.

Oxygen sensors use an internal heating element to bring them up to operating temperature because they have to be hot before they generate a signal. If a fault occurs in the heater element or heater circuit, it will usually set a code in the P0030 to P0064 range. An external fault does not require replacing the O2 sensor, but an internal heater fault does. Oxygen sensor external circuit faults may set codes in the P0130 to P0147 range). This includes things like loose, corroded or damaged O2 sensor connectors or faults in the wiring harness.

If an oxygen sensor code is in the P0150 to P0167 range, it usually means a sensor is reading out of range (voltage too high, too low or unchanging). This usually, but not always, indicates a bad O2 sensor that needs to be replaced. The code will indicate the location of the sensor (cylinder bank 1 or bank 2 in a V6 or V8 engine), and the number of the sensor (1 is usually the first sensor, while 2 may be a second sensor or a “downstream” sensor by the catalytic converter).

Replacing all the O2 sensors on a high-mileage vehicle may be recommended if one or more sensors have failed.

Courtesy Counterman.