In the latest video posted on the “MEYLE TV” YouTube channel, the “MEYLE Mechanics” explain how repair professionals can make shock absorber testing a routine task during vehicle inspection.

In the latest video posted on the “MEYLE TV” YouTube channel, the “MEYLE Mechanics” explain how repair professionals can make shock absorber testing a routine task during vehicle inspection.

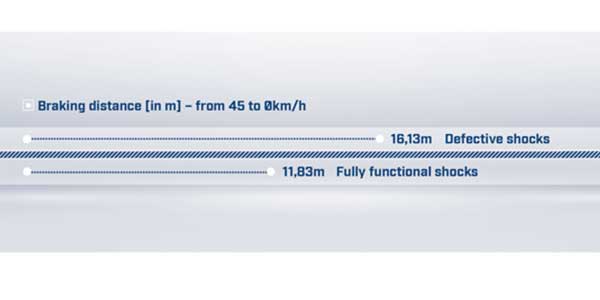

Potholes, bumpy roads, heavy loads or towing are some of the scenarios putting shock absorbers under heavy strain. When combined with other environmental factors, including dirt, humidity or road salt, shock absorber life can be dramatically reduced. As shock absorber performance deteriorates, driver safety is no longer guaranteed. The tires lose road grip, resulting in reduced vehicle stability and increased stopping distance. At the same time, poor road grip affects the tires’ lateral guiding capabilities when cornering, and state-of-the-art driver safety systems, including ABS, ESP and TCS, may not be working properly.

Workshops performing a shock absorber test as part of the servicing routine offer their customers safety-critical added value. In their latest video, the MEYLE Mechanics guide repair professionals through different methods of diagnosing shock absorber damage. In some cases, visual inspection of the tires may reveal areas of local wear – a typical symptom of shock absorber damage. Sometimes, a test drive reveals the telltale signs: if the vehicle feels unresponsive, especially when cornering, or does not go straight without steering corrections or if there are loud clunking noises coming from the car, the shocks are due for replacement.

MEYLE offers a range of 650 high-quality MEYLE‑ORIGINAL shock absorbers catering for some 214 million vehicles registered across Europe.

To watch the latest “MEYLE Mechanics” video on shock absorber function testing, click here.