Whether you’re talking about a three-cylinder hatchback or a supercar, motor mounts have to keep vibrations away from the driver and keep the engine mounted to the frame. As engines and drivetrains have become quieter and more powerful, motor and transmission mount have had to become active or be able to change compression rates.

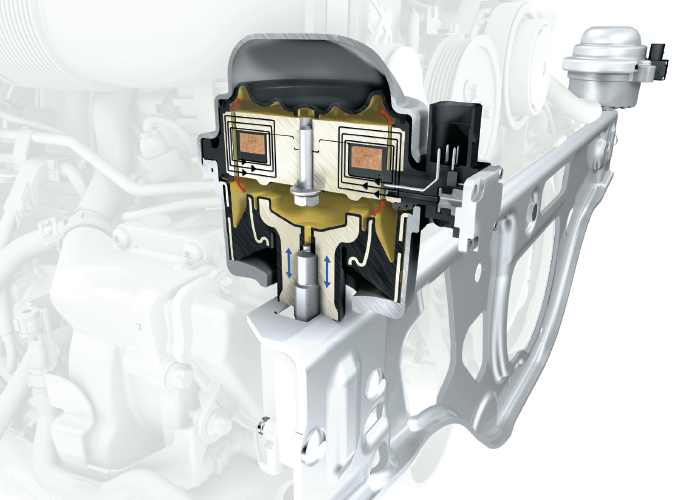

The first innovation was the fluid-filled motor mount. As the engine put force on the mount, the fluid was transferred between chambers to change the compression rate of the mount.

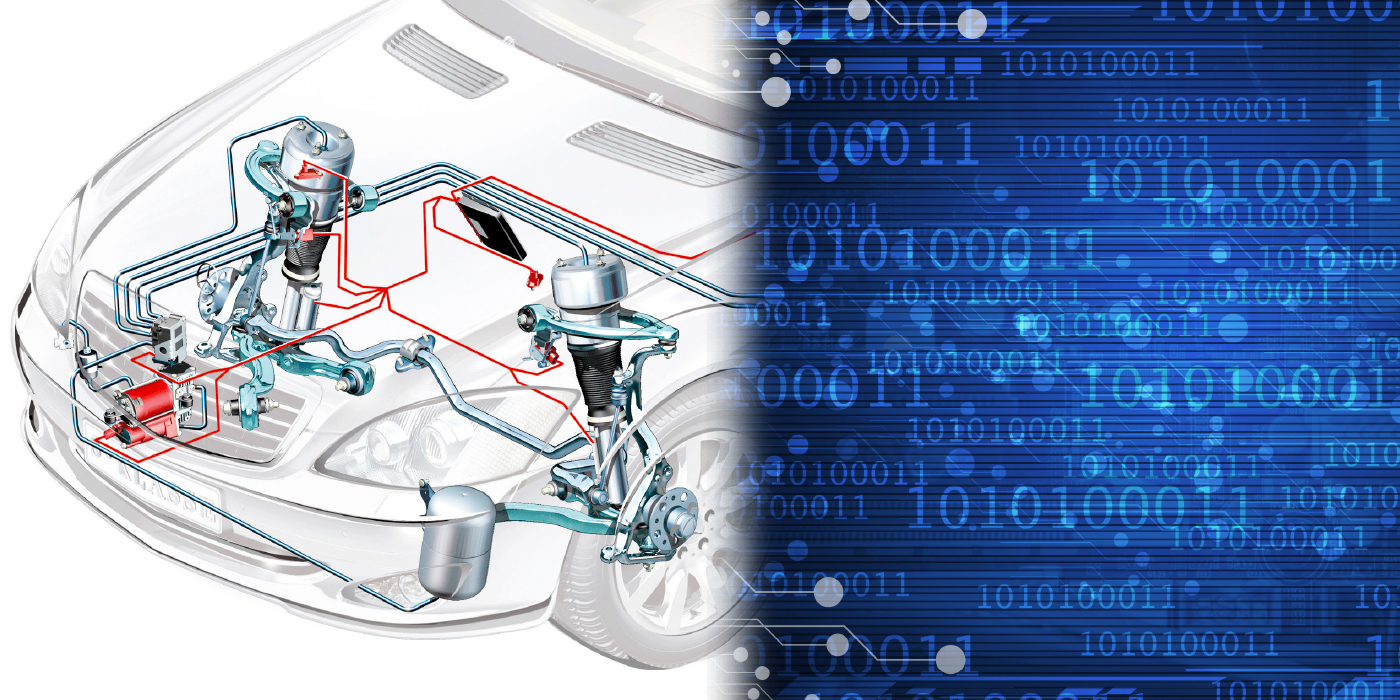

The next evolution was a system that could change the stiffness of the mount depending on the load on the engine. Such a mount can be relatively soft at idle to absorb the unwanted shakes produced by widely or unevenly spaced cylinder firings, then stiffen up at higher engine speeds and loads to limit unwanted engine motions. It’s the best of both worlds, but it does require some type of external controls and inputs.

Most of these mounts used engine vacuum to adjust the stiffness of the mount. Early mounts had vacuum applied directly from the engine. Later mounts use a solenoid controlled by a pulse width modulated signal from the ECM to better control the valving.

The greatest leap forward for engine mounts has been the magnetorheological fluid, which contains metal particles suspended in oil. When exposed to a magnetic field, the fluid changes viscosity. If you use an electromagnet, you can actively change the viscosity and dampenining characteristics in milliseconds.

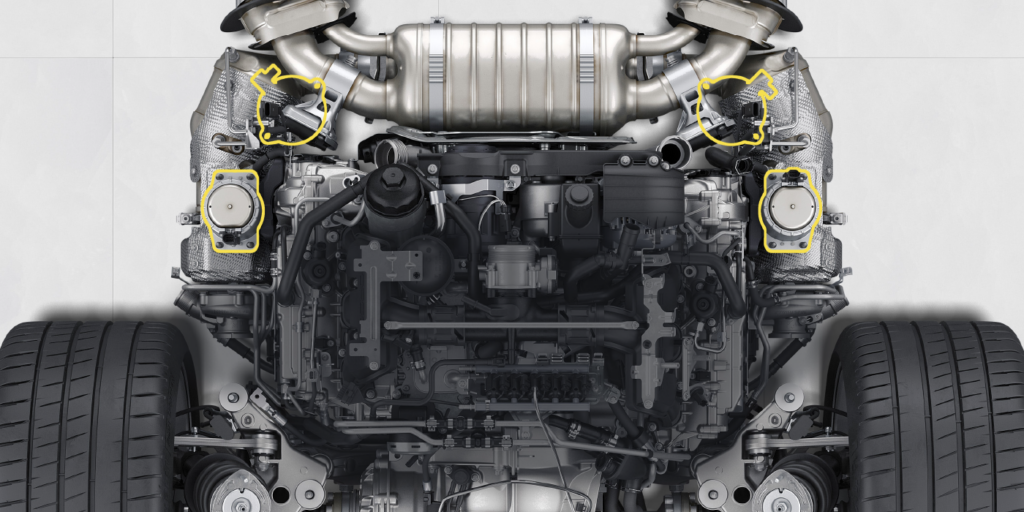

Porsche Active Drivetrain Mounts are filled with magnetorheological fluid. The mounts have two chambers, between which is an electromagnet.

At low engine speeds, the fluid flows freely to provide a more comfortable driving experience. As conditions change, so does the viscosity of the fluid. The control of the fluid is up to the ECM, but it is looking at a lot of inputs.

For example, if the driver is shifting gears it will change the stiffness of the mounts when the clutch pedal is depressed or the driver pulls on the paddles behind the wheel. If the driver is exiting a corner, it will change the viscosity of the two mounts independently to smoothly apply power.

The behavior of the mounts changes if the driver selects a sport mode to give them more feedback.