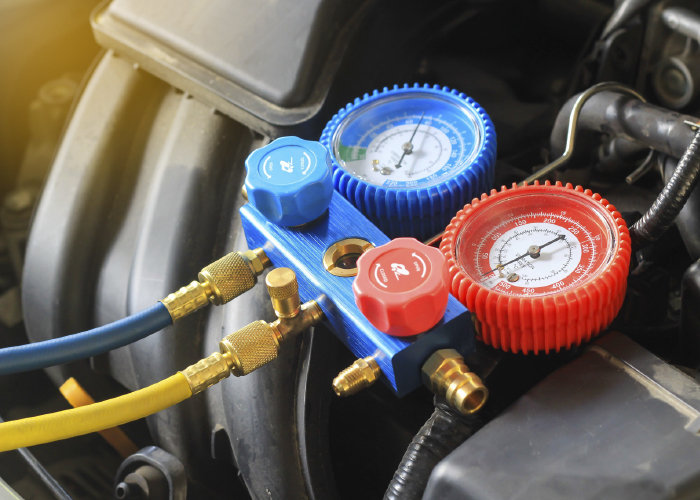

Summer is just around the corner, and this is a perfect time to get your air conditioning machine serviced before the busy A/C season hits. As the summer winds down and we move into the cooler months, most A/C machine usage winds down as well, with the machine sitting idle for longer periods of time, often unserviced at the end of the season. Now is the perfect time to get it ready to prevent any unwanted “downtime” from a machine that wasn’t serviced. Let’s look into what you can do to get your equipment ready.

First, change the vacuum pump oil. Most A/C machines will warn you when it is time to change the oil – typically around 30 hours of use. The last thing a shop owner wants is a tech ignoring the change oil reminder during a busy A/C season and damaging the vacuum pump. So, even if it’s not ready quite yet, it’s good practice to do it in the spring. After the oil has been changed you can go into the service settings of the machine and perform the oil counter reset.

Next, change the filters. After approximately 150kg of refrigerant has been recovered, the “change filter” alarm will appear on the machine. Most of the filters are relatively easy to change and can be obtained from the manufacturer of your brand of machine. Don’t forget to select “filter replaced” in the service menu after you’re done.

Also, check for software updates. Many newer machines have software that can be updated as new cars come out yearly. Depending on your brand, you may be able to do this in-house. While others may need a service rep to come install it for you.

If you have oil injection, it’s a good idea to drain the old oil that was recovered over the season. It’s also a good practice to change the new oil container, as well. That oil has been sitting all winter long and it may be contaminated with moisture. PAG oil is hydroscopic meaning that it absorbs moisture. If the moisture content is too high, it can contribute to the formation of acids and corrosion, resulting in damage to components and leaks.

If your machine has a printer, check the paper. Does the paper need to be replaced? Perform a printer test and verify the printer cartridge (if equipped) doesn’t need replaced, as well. Make sure the printout is legible to read for you and your customers.

Calibrate! Some machines will allow the internal refrigerant cylinder scales to be calibrated in-house. Follow the instructions in the service manual of your given machine to calibrate the scale. Today’s vehicles are using less refrigerant than in years past and a couple ounces off is all it takes to affect the performance of a vehicle’s air conditioning system.

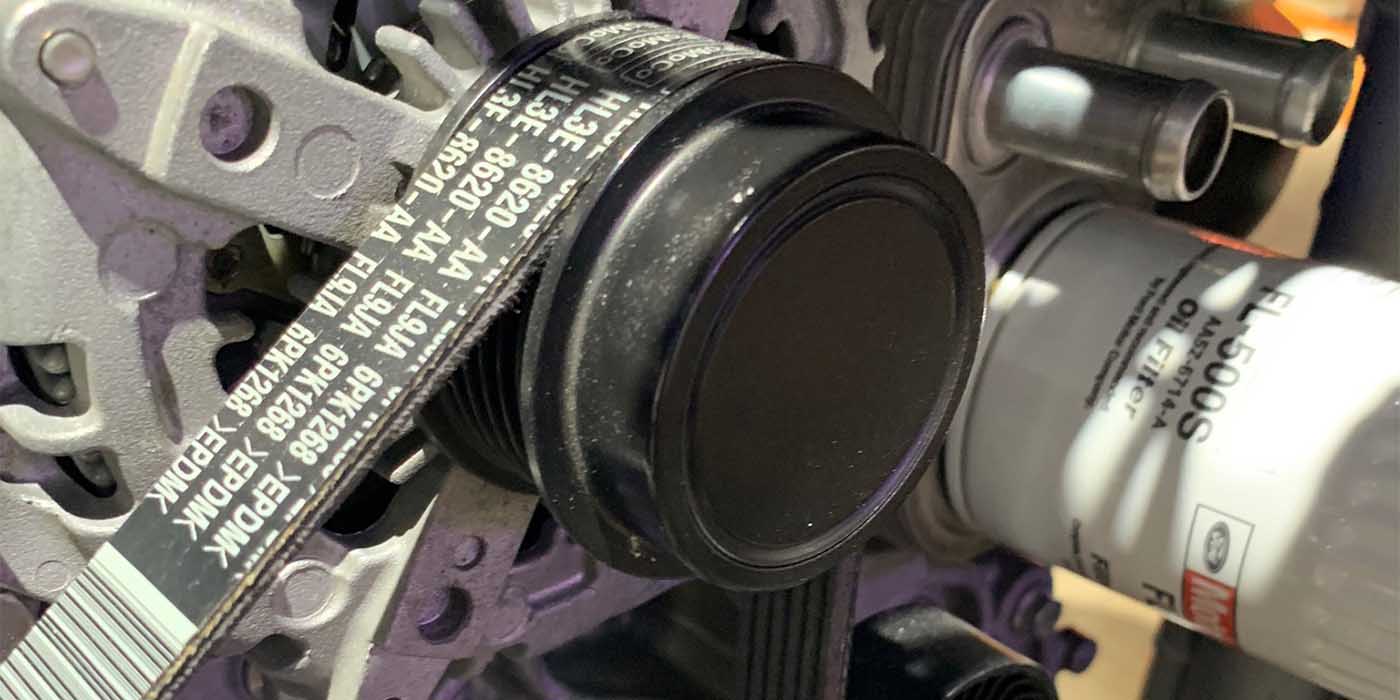

Perform a thorough inspection of the hoses, fittings, and quick-connect adapters. Make sure the hoses are pliable and clean. Inspect for any cracks developing on the hoses and replace them, if needed. Verify the quick connectors are clean and operate as designed.

Check the condition of the power cord. Make sure it is safe and not cracked, damaged, or frayed anywhere along its length. Replace the power cord if any damage is found during your inspection.

Lastly, give it a good cleaning! Remove any dirt or oil that may be on it. Using a mild soap, wipe down the cabinet and control panel. Don’t use harsh chemicals such as brake cleaner as it can damage the control panel screen.

With a few simple steps, you can ensure that your A/C machine is properly maintained and ready for the upcoming A/C season! Not to mention, proper maintenance will lead to a longer machine life. That sounds “cool” to me!