A growing number of vehicles are equipped with electronic parking brakes that automatically engage the parking brake when the transmission is shifted into park or it detects that the vehicle is on a hill. If you are doing a brake job on a vehicle with an electronic parking brake (EPB), you will need a scan tool with the proper software for the parking brake system to retract the calipers, adjust the cables and perform diagnostics.

There are no shortcuts. You can find videos that involve removing the electric motor, jumping connectors and disassembling the parking brake mechanism. But, these methods are risky and can damage the vehicle and kill productivity. Unapproved methods will set malfunction codes, and the worst-case scenario is that you could damage the unit.

System Types

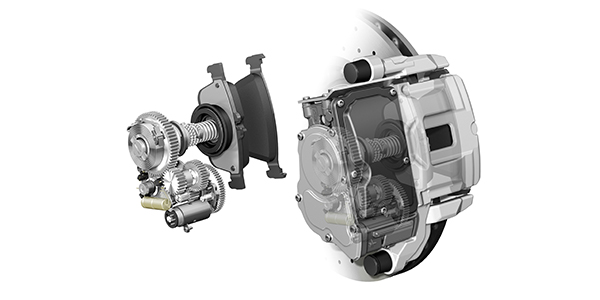

On one end of the spectrum, there are EPB systems with a stepper motor on the back of the caliper that actuate the piston. These systems typically require a scan tool to replace the rear brake pads. But, some systems can be retracted using the infotainment or other menus to put the rear brakes into a service mode.

On recent platforms, they have outfitted the motors with a sensor that can measure brake pad wear and adjust the pads for the least amount of drag. The sensor will also adjust the pads every 621 miles when the vehicle is off. During this adjustment on some vehicles, the pad thickness is calculated.

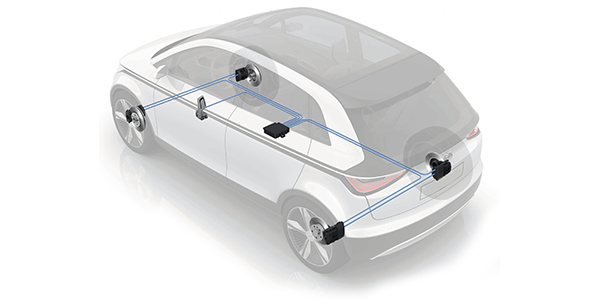

On the other end of the spectrum, there are cable-actuated EPB systems. These systems use conventional calipers, but a motor replaces the lever or pedal in the cabin. All cable systems have a built-in program that adjusts for slack in the system and that runs at certain intervals. Some of these systems require the use of a scan tool to adjust the parking brake. These systems can recognize if the cables become elongated and will set a code. They can be found on platforms such as GM, Ford, Jaguar, BMW, Subaru, and many other domestic and import nameplates.

Performing diagnostics on these systems can be frustrating to the under-equipped and under-trained technician. The typical customer complaint is that an intermittent “parking brake fault” is displayed in the driver information center.

Diagnostics

The most important thing about EPB systems is how they measure movement of the cables or calipers. The systems use Hall effect sensors to track the number of turns of the motor(s). There is another circuit that measures the current the motor is using to actuate the cable.

Inspecting the caliper, cables and motors may not give you a complete picture of what is happening with these systems. Having access to a scan tool can reduce diagnostic time. It can also provide you with data PIDs for the motor.

The OEMs have built-in bi-directional protocols to retract the parking brake so the pads can be replaced. A dedicated brake tool or enhanced scan tool is able to command these protocols and interrogate the module for codes and faults.

The Electronic Parking Brake Module (EPBM) is the module on the CAN bus of most vehicles equipped with this system. Any missing data for vehicle speed, gear position or brake pedal input will cause a problem with the system.

CAN bus information from the ESC program is responsible for the hill-holding control of the actuator. Shared information for the hill-holding feature comes from the yaw, incline and acceleration sensors, along with gear selection and steering wheel position. The electric parking brake ECU monitors the operation of the parking brake motor and places this information on the CAN bus. Some systems also work with the ABS HCU to hold the brakes on.

Some systems use information from the electric parking brake to track shoe and pad wear. The system will count the number of turns the actuator makes or the position of the stepper motor to determine the thickness of the friction material.

Another diagnostic approach is to check the operations section of the parking brake system in the vehicle’s service information. Some systems will use the parking brake for hill holding if an incline is detected, and some systems have an “Auto Hold” or “Roll-Away Prevention” function that will prevent the vehicle from rolling forward at stops.

Dead Module? Stuck Caliper? Dead Battery?

The biggest problem with these systems is if a malfunction occurs. In rare cases, a dead battery or failed module will cause the emergency/parking brake to remain on. In the majority of vehicles, there will be a section in the owner’s manual addressing how a driver or tow truck driver can disengage the EPB.

If you do find yourself working on a vehicle where the electronic parking brake will not disengage, the first thing to do is look at the basics. Some systems require that the doors are shut and the brake pedal is depressed. Some models may even require the seat belt to be buckled. Simple items like a defective brake pedal or door switch may hinder operation. Also, in some cases, the button may be defective. On some vehicles, the operation of the switch can be verified with a scan tool.

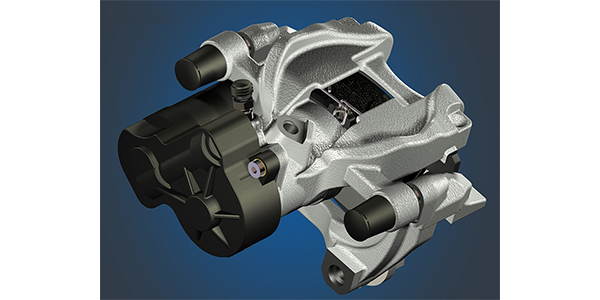

A last-resort option is to manually release the caliper. On some VW and Audi models, it is possible to remove the motor from the caliper and wind back the piston. On cable-pull systems, the actuator may have a shaft that can be turned to release cable tension. Another option is to disconnect the cables if they’re accessible and have some slack.

If the system is annually disengaged, it is critical that the system is adjusted for piston position or slack before the vehicle is returned to the customer.

Article courtesy Brake & Front End.