From the driver’s seat, it may seem that not much has changed with a car over the past 50 years or so. Sure, there may be digital speedometers, heads up displays and certainly more accurate guidance systems but looking through the windshield, the steering wheel looks pretty much exactly the same as in the past.

Behind the scenes, it’s a different story; one your customers may not expect or understand.

Historically, steering systems on cars were hydraulic. They utilized a pump to move the fluid to power assist either a steering gear or rack and pinion. This pump was driven by the vehicle’s engine, usually via a belt. This was only an assist, and the driver was moving the wheels. Today, the driver still has control of the vehicle, but the assist is coming from an electrical source.

To understand the basic EPAS system it is important to know the three basic types.

The first is a column-mount system – as you might expect, this type mounts the assisting assembly in the column. The column-mounted EPS uses an electric motor on the steering shaft to add assist when turning the steering wheel. This design has the benefit of keeping the electrical components inside the vehicle and out of the elements. Unfortunately, mechanical repairs to these components can require disassembly of the instrument panel and other systems.

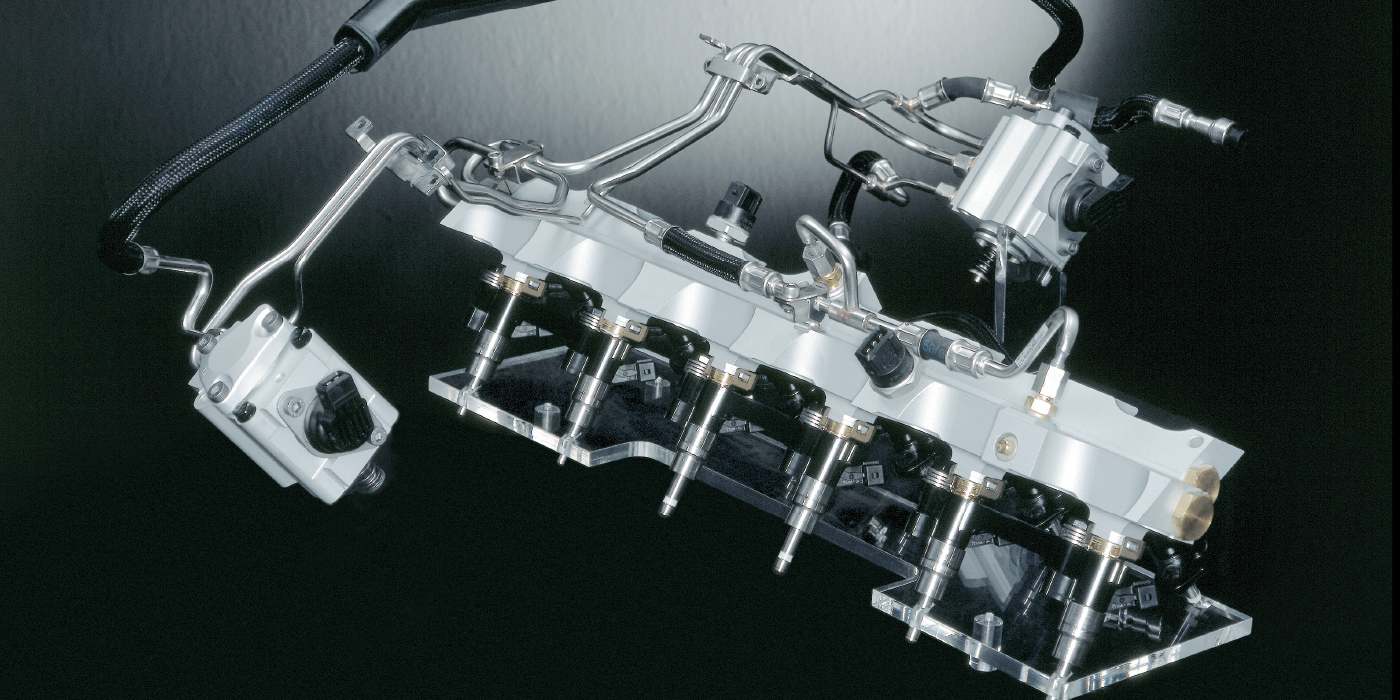

The second type of system is an electric hydraulic type of assist. The basic design is similar to belt-driven hydraulic power steering pump systems, but the big difference is that isn’t driven by vehicle engine power – it utilizes an electric motor to drive the pump impeller.

The final type of assist is an electric rack and pinion system, which actually comes in four basic categories. The concentric or axial driven units integrate the motor into the rack and the armature drives a screw driven shaft that moves the rack. The belt driven style uses an electric motor and a belt to drive the movement. The final two utilize motor-driven pinions, either driving the rack input shaft on a single pinion design, or driving the rack bar shaft on a dual-pinion.

Regardless of which type of system your customer has concerns with, it’s likely that your investigation will involve sensors at some point. The first sensor is the steering wheel position sensor. The system needs to know which way the driver is steering the vehicle. The system utilizes the steering wheel position sensor to read the intended direction.

EPAS systems utilize the speed sensors data from the anti-lock brake system to indicate rotational speed of the wheels.

There is a torque sensor in these systems that tell the steering to assist the amount of torque a driver is putting on the steering wheel. The combined information from the speed sensors and the torque sensor allows the system to calculate how much assist to give the steering system.

EPAS systems may also use a dynamic sensor. This sensor indicates vehicle movement and direction of travel. This allows the vehicle to utilize braking, throttle and in some cases low-effort steering assistance to correct differences in steering direction and actual travel direction.

More complex systems may present your customers with higher-than-expected repair bills. Your understanding, and explanation, of power steering system operation will help eliminate their uncertainty.

This video is sponsored by The Group Training Academy.