MODELS w/5×120 wheel bolt pattern:

- F06 (6 Series Gran Coupe),

- F07 (6 Series Gran Turismo),

- F10 (5 Series Sedan),

- F12 (6 Series Convertible),

- F13 (6 Series Coupe),

- F15 (X5 Sports Activity Vehicle),

- F16 (X6 Sports Activity Coupe),

- F22 (2 Series Coupe),

- F23 (2 Series Convertible),

- F25 (X3 Sports Activity Vehicle),

- F26 (X4 Sports Activity Coupe),

- F30 (3 Series Sedan),

- F31 (3 Series Sports Wagon),

- F32 (4 Series Coupe),

- F33 (4 Series Convertible),

- F34 (3 Series Gran Turismo),

- F36 (4 Series Gran Coupe),

- F39 (X2 Sports Activity Coupe)

- MODELS w/5×112 wheel bolt pattern:

- G01 (X3 Sports Activity Vehicle),

- G02 (X4 Sports Activity Coupe),

- G05 (X5 Sports Activity Vehicle),

- G06 (X6 Sports Activity Coupe),

- G07 (X7 Sports Activity Vehicle),

- G12 (7 Series Sedan),

- G14 (8 Series Convertible),

- G15 (8 Series Coupe),

- G16 (8 Series Gran Coupe),

- G20 (3 Series Sedan),

- G29 (Z4 Roadster),

- G30 (5 Series Sedan),

- G32 (640i xDrive Gran Turismo),

- I01 (i3),

- I12 (i8 Coupe),

- I15 (i8 Roadster)

Customers may experience a ticking noise coming from the front wheels while cornering without the brakes applied. This is especially noticeable at low speeds. And, of course, the vehicle must be moving.

This may be caused by microscopic movement of the contact interface between the inner brake disc and the wheel bearing flange on vehicles equipped with lightweight brake discs. To correct the issue, a friction ring must be installed between the brake disc and the wheel bearing flange.

Service Procedure:

- Verify that the noise is produced when cornering without the brakes applied.

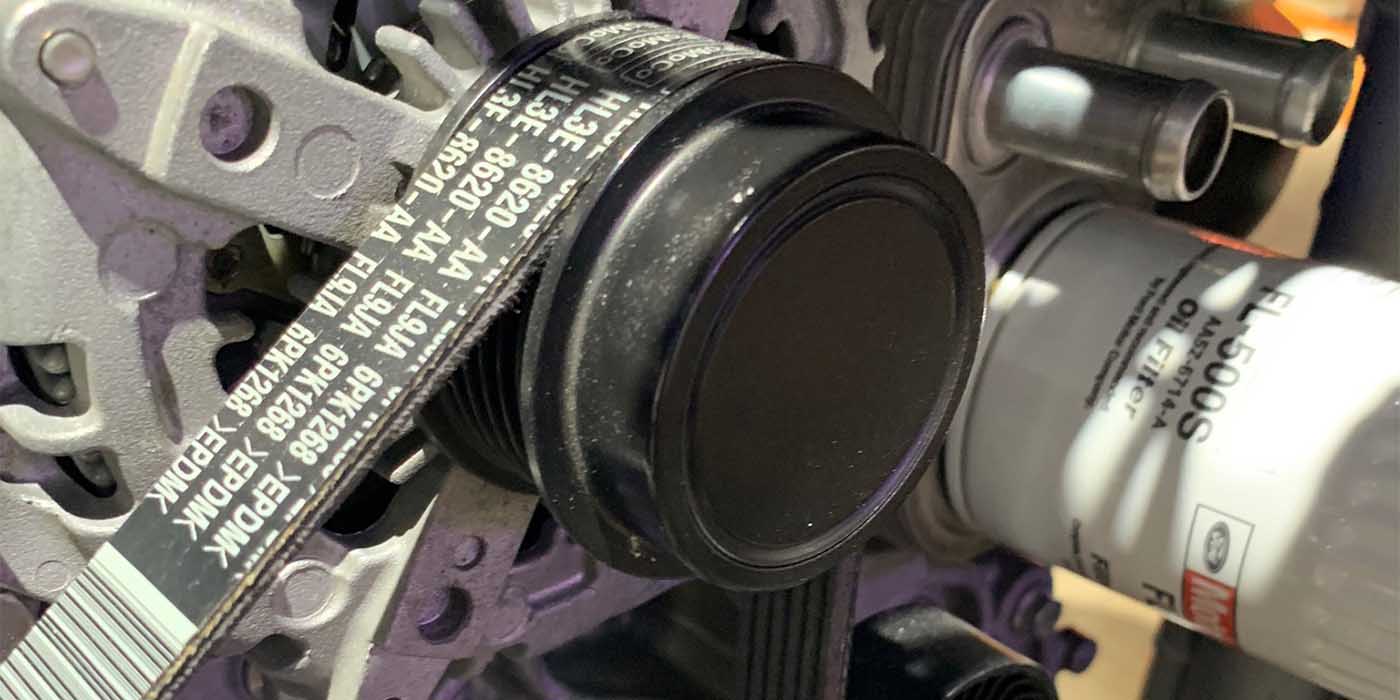

- Verify that lightweight brake rotors are installed on the vehicle (Figure 1).

- Remove the brake discs. Clean the wheel bearing flange with brake cleaner.

- Install the “friction ring” on wheel bearing flange (Figure 2).

- Repeat the procedure for the opposite front wheel. Reassemble in reverse order.