CC:

When we talk about fuel pumps, we immediately think of electrical pumps in the tank and fuel pump modules. It’s what the majority of cars are equipped with today.

There are, however, quite a few carbureted old cars and trucks on the road that still operate with a mechanical fuel pump. Sooner or later, you’re going to have one in the shop, and you’ll need to know the basics to diagnose a fuel system problem.

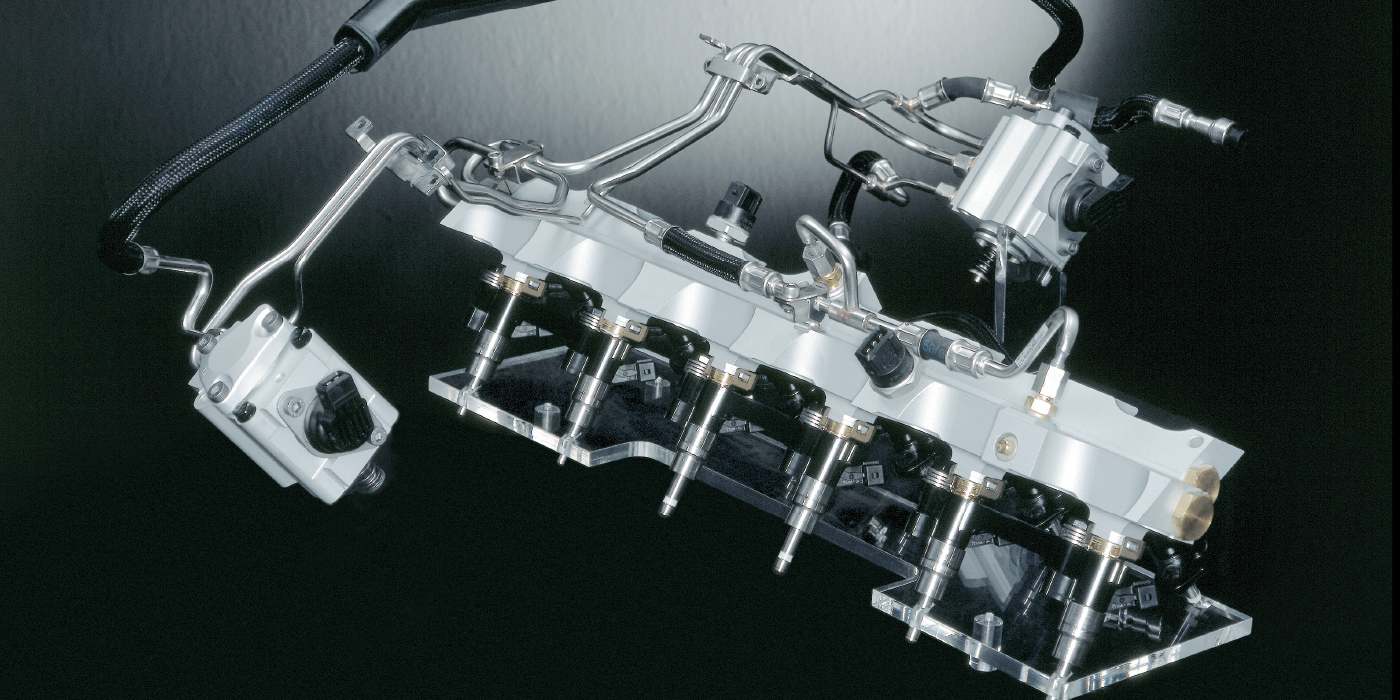

Most mechanical fuel pumps are driven by the camshaft. There is a lever that extends out of the pump which in turn either rides directly on a camshaft lobe, or in some cases there is a pushrod between the lobe and pump lever.

The lever pivots where it enters the pump, transferring motion to a diaphragm and valve assembly, which pressurizes the fuel and delivers it to the carburetor. The pressure developed by a mechanical pump is not as high as we are used to with electric pumps. It’s usually only about 5-6 psi, and that’s all you need. Anything higher than that can actually force past the needle and seat and flood the carburetor.

Diagnosing a fuel system with a mechanical pump is a straightforward process, and like any fuel system, pressure is the first thing to look for. Since carbureted vehicles aren’t equipped with a test port, it’s a common practice to disconnect the line from the carburetor, attach a hose to it and place it in a container, then crank the engine. You’ll know immediately if fuel is being delivered, and if you attach the hose to a gauge, you’ll see the pressure output of the pump.

There may be cases in which you need to monitor fuel pressure with the engine running, and you’ll have to make an extra fitting between the fuel line and carburetor, so you can tee in a pressure gauge. It takes a little extra work, because you don’t want to cut or damage the solid line leading to the carburetor.

If fuel delivery is a problem, a tip to remember is to closely inspect all of the fuel lines and hoses. There are normally a couple spots from the tank all the way up to the engine where there’s a short section of hose instead of hard line. A pinhole or leak in either the line or one of these hoses will cause the fuel pump to draw in air instead of fuel.

Never overlook the fuel tank. It’s very common to get contaminants in the gas tank of an older vehicle, especially if they have sat for a while. The pickup tubes at the base of the sending units often have fine screens attached to them, and they can plug up very easily. If the gas gauge doesn’t work, that’s another clue that there could be rust and corrosion in the tank.

The bottom line, if you’ve got a clean tank, good lines, a good pump, and no problems with the pump drive, you’ve got fuel pressure. When replacing a mechanical pump, be sure to use a high-quality pump from a reputable manufacturer. Fuel pressure specifications are just as important on these old cars and can cause driveability problems just the same on an old vehicle as they will on a new. Thanks for watching.