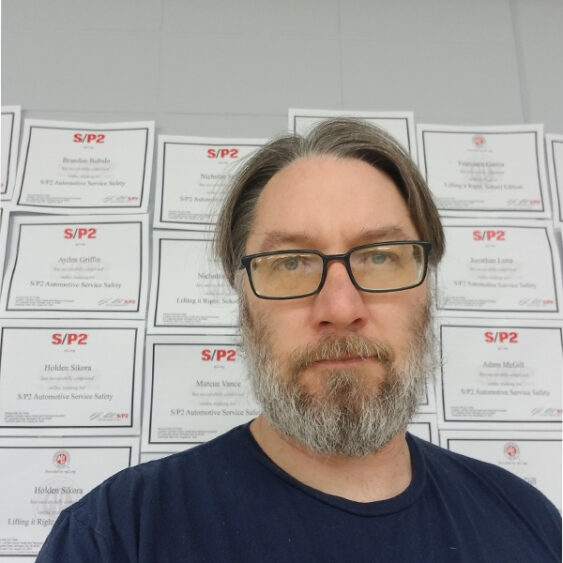

After taking automotive and collision repair classes in high school and college, Steve Barnes of AK Smith Career Center in Michigan City, Indiana says he knew he was set to succeed in the automotive industry. After graduation, that’s what he did.

“After taking Vocational Auto Trades in my junior year of high school and Auto Body Repair as a senior, I graduated from Rogers High School in Michigan City in 1993,” Barnes says. “I knew I wanted to work with cars from around the age of 10. I loved taking things apart and finding out how they worked. I even put them back together and make them work again….mostly.”

Barnes attended Lincoln Technical Institute in Indianapolis after high school and graduated with degrees in Automotive Service and Service Shop Management. After working as a technician for several years, he says he went back to visit his old instructors to thank them for putting him on that path. “I discovered it was the instructor’s job I was after the whole time,” he says. “I realized the impact they had on students’ lives and I wanted to be a part of that.”

Barnes explains that following graduation he had worked as a technician for over 15 years before striking out on his own and opening his own shop. Realizing he wanted something more but believing he would have to go back to school to become a teacher, he let that dream fall by the wayside. “It became too hard to consider getting another degree once I started a family,” he says. “I ran a small operation for two years before a longtime friend (and customer) told me that our local career center was looking for a long term substitute teacher for their Automotive class. Business had slowed some, so I thought I would check it out. I connected with the director of the school and was hired after a few phone calls and a quick interview.”

Getting back to the classroom wasn’t a simple transition he says, but it provided incentive to stay with it. “My first few days on the job were shaky, but I met with the instructor (also one of the instructors from the high school I attended) and he gave me some great advice. He made it clear he was going to retire soon, and he worked with me for the rest of the year to ‘pass the torch.’ At the end of the year, he said he was going to work one more year and that he would give the director a strong recommendation to hire me as his successor.”

With a year available to hone his skills, Barnes says he spent that summer working in his shop with a new sense of purpose. “’I’m going to be the next Auto Teacher,’ I kept telling customers,” he says. “Still trying to grow my business, I kept education in mind and attended all the training I could get my hands on. I wanted to spend the next year making myself, and my business, the best it could be.”

Then in August, Barnes got the call. “At 3 pm on a Sunday, the school director called me to ask if I was still interested in the teaching position. When I said ‘Absolutely,’ she said ‘Great. I need you to be at the High School at 8am tomorrow morning for new teacher orientation.’ The previous instructor had decided last minute to retire early and the job was mine,” Barnes says.

“I showed up for orientation, got my keys from the secretary and I went to work! This is my 10th year teaching and it’s been the best job I have EVER had!”

Barnes says his own high school instructors were his strongest mentors.

“I try to be the best instructor I can be and to, first and foremost, teach and preach a high level of professionalism to the classroom. That allows them to show the community, other teachers and administrators and, ultimately, the school board that we can be professional.”

This, explains Barnes, isn’t just about fixing cars in their backyards.

“I’m trying to pump out high level professional technicians here. When I first started as a teacher here, I ran the class and the shop like a service center. I try to teach them and train them as if I was training technicians in the field.”

He has refined his methods over the years, he says to teach more fundamentals in the classroom. But he does so in as relatable way as possible.

“One of the first things I tell students each year is ‘I don’t want to stand here and lecture any more than you want to sit and listen.’ So, with that in mind, I have to find things for 40 kids to do in the shop every day.”

He also likes to use motorsports and high performance to keep students interested and engaged.

“We regularly get vehicles donated to our program. We always find new and fun things to do with old cars. We took a Subaru Legacy and an Outback and swapped suspension parts. This raised the Legacy three inches and lowered the Outback three inches,” he says. “We now have a lowrider station wagon that we can use to train students electrical systems by installing a competition sound system and a lifted AWD Legacy we plan to enter into SCCA rally events after making some performance upgrades.”

In an effort to teach ALL automotive systems, Barnes has his students completely disassemble a car bolt by bolt. Living in the “rust belt,” he explains, there’s no shortage of blown brake lines, seized tie rods or leaking oil pans (“Breaking rusted fasteners loose with PB B’laster, of course,” he says) down to the shell – identifying components and systems along the way. “I then show them how to use torches, saws and grinders properly and safely as they dice the remains into small enough pieces for one person to carry to the scrap bin. We use scrap metal money to help fund our projects.

The grassroots efforts definitely pay off, he says. “Several years ago, I received a grant from a local factory to purchase a snowmobile and all the tools and supplies to convert it to a search and rescue vehicle for the state park. We built a trailer from scratch with help from our Welding, Fire Science, Machining and EMT classes to carry injured skiers and hikers back to safety,” Barnes says.

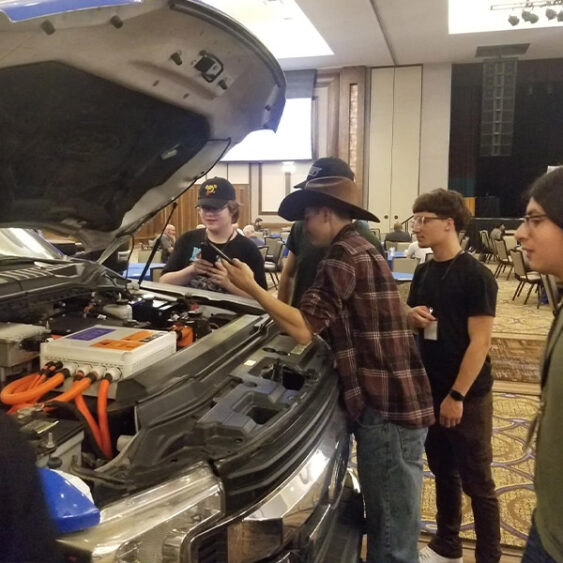

“This year, our focus is on Alternative fuels. I have already taken students on multiple field trips to learn about hybrid drives, diesel technology, and even get behind the wheel of electric cars. We are currently beginning lessons and activities to turn used cooking oil from our Culinary classes into biodiesel to run engines in our class as well as an ambulance and a fire truck we have on site,” he explains.

“I recently became an evaluation team leader for the ASE Education Foundation. I’ve been asked to go to secondary and post-secondary organizations to evaluate them and make sure that they’re at a high level like we are and make sure that all the other automotive instructors and programs are doing what we’re supposed to do,” Barnes says. “I like to use my program and my shop and class as an example for these other schools that I’m going to visit.”

Barnes says being recognized as a candidate for Instructor of the Year is affirmation that he made the right career choice. “It is important to me to prove it to myself, but also to others, that I am a real teacher. I am good at what I do. As the nomination form states, we ARE humble. Why should I be nominated for Teacher of the Year? That’s a hard one. I don’t normally ‘toot my own horn,’” he says. “All I can say is that when talking with members of the community, including parents, business owners, and local officials, I receive praise for the work I’m doing.”

And it’s about more than just patting himself on the back, Barnes says.

“During recent Parent Teacher Conferences, three parents thanked me for reaching their kids in a way no one else had and for brightening their days. Giving students the confidence boost they so desperately need.

“Many students in our community come from poverty, or close to it. When they come to me, they’re tired, hungry and feel beaten down by school and life. I give them a reason to smile. I make a point to have a one-on-one conversation with students EVERY DAY. Most teachers in a traditional classroom setting don’t have that opportunity or luxury. I keep a stockpile of healthy snacks on hand, knowing some kids may not get fed outside of school.

“The future may not look very bright to some kids. So, I try to open their eyes to the possibilities of a great career they can enjoy. I will take students on several field trips to tech schools and colleges this year, knowing their parents may not have the means to do so. We will be visiting employers like dealerships, independent shops, and career fairs. We even plan on checking out some speed shops and tuners. The trips we take are in small groups. No more than 10 at a time. This provides more individual time where the students can bond with each other and with me. This is the connection a lot of students are missing from their lives.”

Barnes knows that not every student in his class wants to be a technician – and that’s fine. “My goal is to show these kids some skills and let them see that they can do all kinds of cool things. A very artistic student didn’t want to work in groups fixing cars. One day, showed me his notebook full of sketches and drawings and he was upset because the book was full and he didn’t have money for a new one. Now, I have lots of notebooks I could give him, but instead, we drew up a plan and found the materials for him to build a steel notebook. He used 3/16˝ plate for the covers, thin aluminum sheet metal for pages, and heavy key rings for the binder. Now he can use pencil or dry erase markers on this notebook for the rest of his life. I get a little weepy when I see this kid who suffers from depression and anxiety smile and get excited about his project,” Barnes admits.

“I could go on and on about stories like this, but every teacher who is nominated can. We’re all working hard and giving this job everything we’ve got to make these kids successful. That means showing them skills. Opening their eyes to their own potential.”

For more information on the 2023-2024 B’laster Instructor of the Year program or to nominate a worthy instructor, visit Tomorrow’s Technician today.