CC:

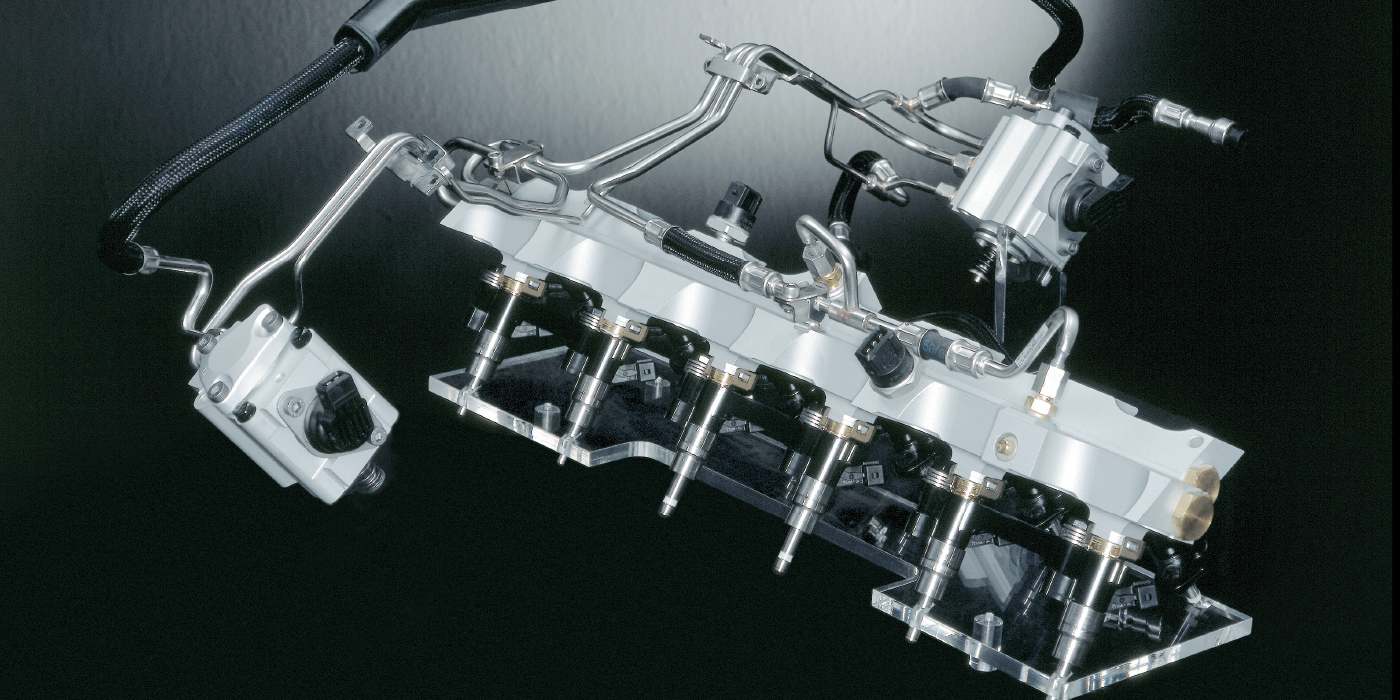

Most direct injection systems use PZO pressure sensors or transducers on the low and high sides of the fuel system. They typically have three wires going to the sensor. One wire provides the reference voltage, which generally is 5 volts, and the sensing element changes resistance and turns a reference voltage to signal voltage. The third wire is almost always a ground. The ECM will turn the signal voltage into a calculated pressure with a plus or minus 2% accuracy.

Measuring the values with a scope or multi-meter will not yield any critical information except input of the reference voltage and if the circuit is open or shorted. So always look at the value with a scan tool. High pressure sensors may use a metallic membrane on a resistance bridge. When pressure is applied, the bridge generates a change in resistance that will cause a difference in the applied voltage sent out using the signal voltage wire.

If the sensor detects a lower than normal pressure at the fuel rail, it can send a P0087. This code does not indicate the fuel pump is faulty. You will still have to inspect the entire fuel system from the tank to the rail. Problems like a fuel leak at the rail or an impact to the bottom of the fuel tank can cause a P0087 code. If the fuel pressure is below specifications, the engine could run too lean due to the pump not producing enough volume. This will cause codes P0171 for bank one and, or P0174 for bank two running to lean.

Both the high and low pressure sensors are very reliable, but when they fail, it typically results in an open or a short to power a ground. It is rare for these sensors intermittently to fail or give inaccurate readings. So when you observe the data from these sensors using a scan tool, the numbers will be implausibly low or high. Sometimes you might get a code P0191 or P0193 for implausible readings or a circuit failure.

The fuel pressure sensors help to determine the duty cycle of the intake pump. The duty cycle is the ratio or percentage of on to off time when 12 volts is applied to the pump or solenoid. This is known as pulse width modulation. As the duty cycle increases, the volume of fuel delivered to the rail increases while the pressure remains in a targeted range.

You can observe the duty cycle of the fuel pump three ways. First, it can be observed as a PID on a scan tool. Second, using a scope, you can observe the switching of the duty cycle as a waveform. Third, you can use your volt meter. Since most meters have an RMS feature that averages the voltages, the voltage reading will be between 2 and 5 volts at idle. If your meter has a duty cycle function, you can read the duty cycle as a percentage.

Observing the duty cycle can give you an indication of the health of the fuel pump, and if the engine management system and fuel pressure sensor are able to control the fuel pump. It can also be used to confirm that a new fuel pump cured a low fuel pressure condition.

With the abundance of information like codes, PIDs, and voltage readings at the pump, you can diagnose, repair, and confirm an underperforming fuel pump.

Thanks for watching.

This video is sponsored by Carter Fuel Systems.