Fuel Pump Codes And Control: Keeping Pressure In The Zone

The first electric fuel pump circuits were very simple. The pump circuit usually involved a relay and fuse. The control side to the relay was typically wired to an ignition circuit or key switch. The control of the fuel pressure was performed with an analog regulator that could keep a static pressure and adjust for loads with a vacuum signal.

The Carbon Deposit Conundrum

During some combustion events, a droplet of fuel or oil is transformed into a substance that can become a carbon deposit. This typically happens when there are conditions that are outside of the normal operating conditions.

Fuel Trims!

Understanding fuel trims is the gateway to diagnosing common emissions problems. However, before we begin to use this information, specific criteria must be met in order for the PCM to gather accurate information.

VIDEO: The Role Of Dispersants In Engine Oil

Andrew Markel discusses the formation of carbon during the combustion process, and how the proper engine oil can prevent sludging in the engine.

VIDEO: Three Tips For Engine Replacement

Andrew Markel discusses engine replacement after a failure, and three important components to focus on with the remanufactured engine.

Diagnosing Throttle-By-Wire Problems

The main reason for the switch to Throttle-By-Wire (TBW) or Drive-by-Wire is that it allows the ECM to work in harmony with other engine control systems such as cruise control, traction control, torque management and stability control.

GM Tech Tip: Black Smoke And Rough Idle On Cold Start

Working on a 2009-2014 GM vehicle? Here’s what to do about black smoke and rough idle on a cold start.

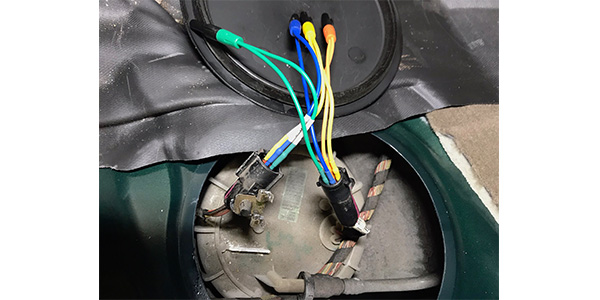

Fuel Tank R&R: Avoiding The Dreaded Second Drop

Nothing is worse that a comeback after a fuel tank has been dropped. Here are some tips that can help you avoid comebacks and dropping the tank for a second time.

VIDEO: How Misfire Codes Get Set

Andrew Markel discusses misfire codes, and how the camshaft and crankshaft position sensors detect rotational anomalies to set them.

Diagnosing, Servicing & Replacing Batteries

Just last summer, I had three batteries pass a conductance test, but fail to crank the engine on a sustained basis. The conductance tester indicated that these batteries were “good,” but they tested well below 100% capacity. In two cases, I was pursuing parasitic battery drain problems with used batteries. In another case, I had a new battery that would pass a conductance test, but not accept a recharge, said Gary Goms, Import Specialist Contributor.

VIDEO: When Oil Level Sensors Fail

Jason Stahl tells us how oil level sensors work as well as the conditions under which they can fail.

Klein Forest High School Instructor Named September Finalist For ‘B’laster Instructor of the Year’

Jonathan Couch, our September “B’laster Instructor of the Year” finalist, shares how his “can-do” attitude helped him create an unofficial engine and collision repair program at his school.