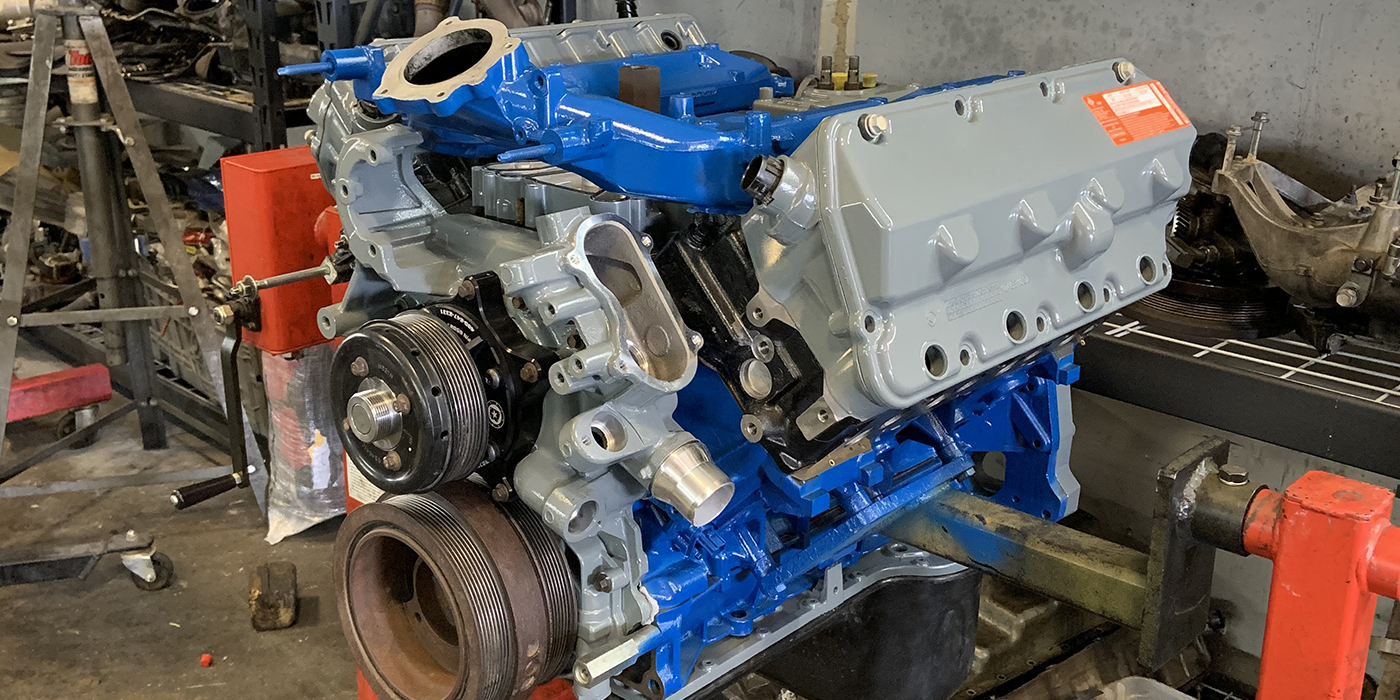

Engine Build: Stage 2 6.4L Powerstroke Performance

With a dead cylinder and damaged block, Powerstroke Performance went crazy rebuilding this 6.4L Powerstroke.

CanDo Introduces Battery Tester And Reset Tool

The Batt R/T makes quick and easy work of battery resets.

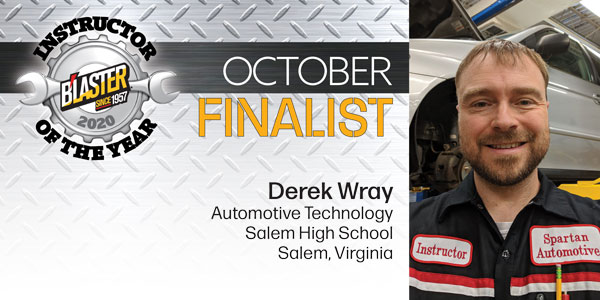

‘2020 Instructor Of The Year’ Grand Finalists Announced

This program recognizes instructors with an unconventional approach and are committed to educating the best future techs.

VIDEO: Can A Weak Battery Start An Engine But Cause Codes?

Andrew Markel and Donny Seyfer discuss what to look for when inspecting batteries. This video is sponsored by MAHLE.

FORD 3.5L ECOBOOST – ENGINE FAILURE CAUSES

Out of warranty and ready to be serviced, Ford models with the 3.5L EcoBoost engine are coming into the shop.

B’laster Instructor of the Year Finalists

Finalists Nominate Rules The Instructor of the Year program recognizes the automotive instructors at high schools, vo-tech programs and community colleges who think outside of the toolbox. Meet the 2021-2022 B’laster Instructor of the Year Finalists! 2022 April Finalist Thomas Chandler Thomas Chandler was worried that his career in the automotive program might be over

VIDEO: The Most Overlooked Brake Master Cylinder Replacement Part

If the seal or O-ring is leaking, it can cause a driveability issues with poor idle quality and lean DTC codes.

Salem High School Instructor Named October Finalist For 2020 ‘B’laster Instructor Of The Year’

Our October Finalist shares how he teaches his students respect and service through a special program that provides veterans car repair.

ASE’s Advanced Engine Performance Specialist (L1) Test Turns 25

ASE’s Advanced Engine Performance Specialist (L1) Test is celebrating its 25th birthday in 2019.

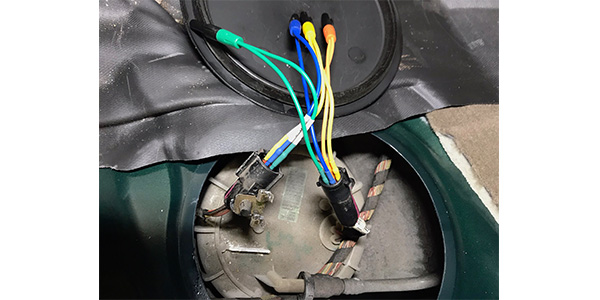

Fuel Pump Codes And Control: Keeping Pressure In The Zone

The first electric fuel pump circuits were very simple. The pump circuit usually involved a relay and fuse. The control side to the relay was typically wired to an ignition circuit or key switch. The control of the fuel pressure was performed with an analog regulator that could keep a static pressure and adjust for loads with a vacuum signal.