If you suspect that an injector is restricted or malfunctioning, an injector balance test may help isolate the bad injector. Scan tools that can disable injectors can assist you in this process. In most instances, you will select this as a function test in the scan tool menu, then the tool will allow you to disable one injector at a time. Many times, the tool will look for engine rpm change, however, engine rpm drop may not be an effective diagnostic method when performing this test.

A more effective method is looking at the voltage changes from the upstream oxygen sensor on the bank that the disabled injector is on. Leaking injectors and some faulty injectors can be missed even when an injector is disabled. If there are other problems with the ignition system or mechanical components causing a misfire, an rpm change when an injector is turned off may not be noticed. If an injector is good, the voltage from the O2 sensor will drop to or below 100mV. Some tools may disable fuel trim during this test, but if the tool does not disable it, an increase in the short-term fuel trim may be observed as well. Beware that if the problem is a restricted or dead injector, the long-term fuel trim may have compensated enough so that the voltage does not change.

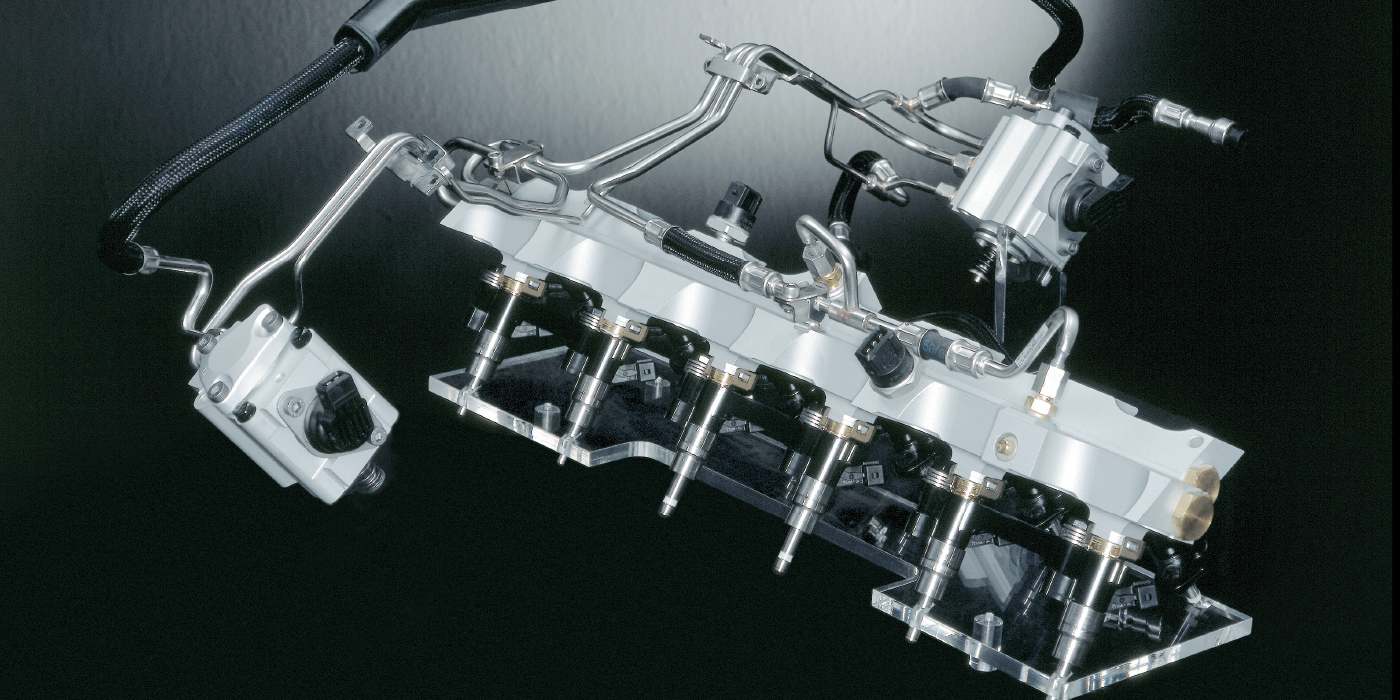

Another effective test is to measure the pressure loss in the fuel rail when each injector is fired and pulses for a set period of time. Use an electronic injector pulse tester for this. As each injector is energized, a fuel pressure gauge is observed to monitor the drop in fuel pressure. The electrical connectors to the other injectors are removed, isolating the injector being tested. The difference between the maximum and minimum reading is the pressure drop. Beware that this is a static test and much less fuel will be flowing than if the engine is running, so in some instances the injector might flow enough in this test, but not enough on a running engine. Ideally, each injector should drop the same amount when opened. A variation of 1.5 to 2 psi or more is cause for concern. No change in pressure, or a very low pressure drop, is a sign the injector is restricted. A higher-than-normal pressure drop indicates a faulty injector that is flowing too much fuel for some reason. It is important to note that this test should only be done one time each injector, unless the engine is started, to prevent washing down the cylinder or hydro locking the engine.

This video is sponsored by Standard Motor Products.