This article will document code P0301 — Misfire Activity on Cylinder No. 1 — a code many of you have run into, but sometimes we have case studies that are worthy of mention.

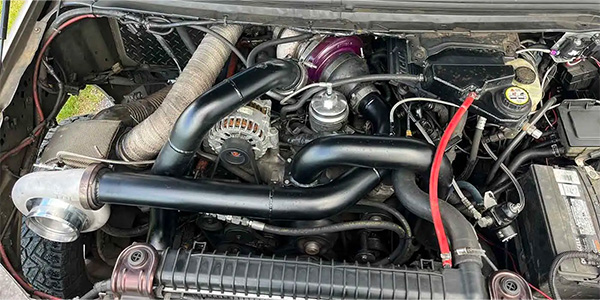

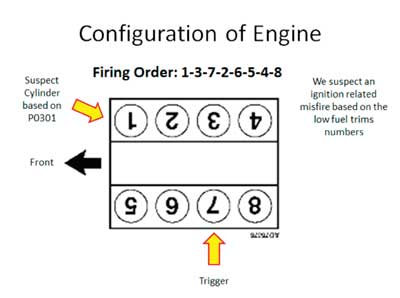

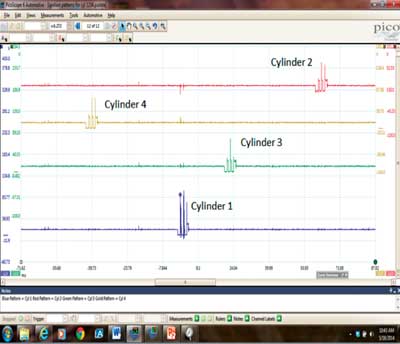

Our subject vehicle is a 2007 Mercury Mountaineer. The vehicle has a P0301 stored in its memory. The lead tech working on this vehicle has determined that there is a mechanical issue with cylinder no. 1. Figure 1 shows the engine configuration for your review.

Misfire codes have become the most challenging codes because they involve very careful review today vs. many years prior.

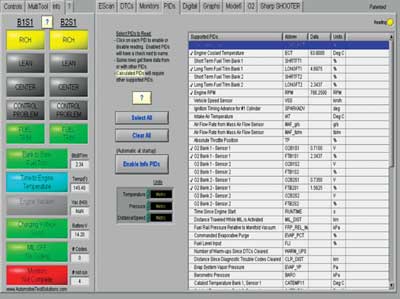

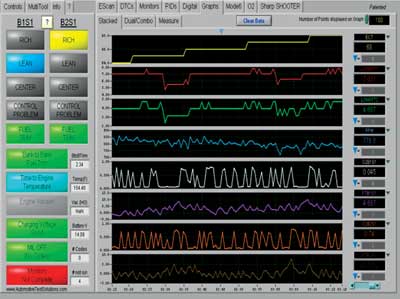

I would like to offer a suggested plan of attack on this vehicle. We will start our game plan by first looking at the scan data. It is suggested to look at the pre- and post-oxygen sensor activity and note what is happening. Our subject vehicle has good switching activity on the pre-oxygen sensor, indicating that the vehicle is in fuel control, but we noted that the post-oxygen sensor has a slightly higher than normal voltage value, implying that this Mountaineer may have a tendency to run slightly rich.

The next step is to review the fuel trim values. This vehicle’s fuel trims show fairly low values, suggesting that the misfire activity may be ignition related. This, of course, must be proven.

Let’s review our process for success:

- Review pre- and post-oxygen sensor activity.

- Review fuel trims (short term and long term). The total correct will be their summation. If the fuel trims are not very significant in value, the problem is possibly ignition related; if the fuel trims are significant in value, the problem is possibly fuel related.

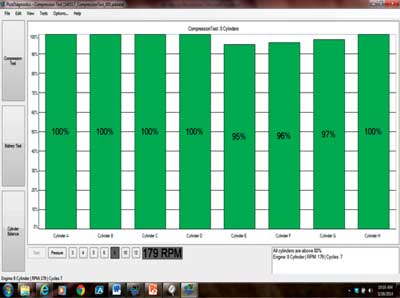

- You must then perform a mechanical analysis to see if the vehicle is mechanically sound. This will help rule out any mechanical issues.

- After confirming there are no mechanical issues, you will check for an ignition- or fuel-related failure based on the fuel trim and oxygen sensor data.

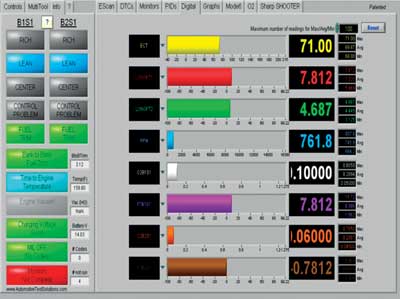

Figure 2 shows the fuel trims and oxygen information from the Mountaineer.

The scan data on this vehicle appears to be good; there were no signs of adverse activity other than the P0301 code that was set in the PCM’s memory. See Figures 3 and 4.

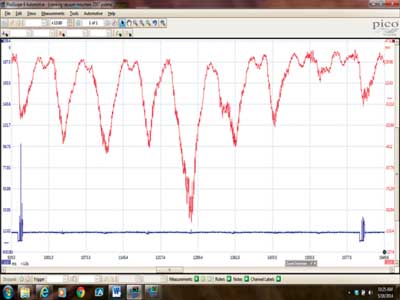

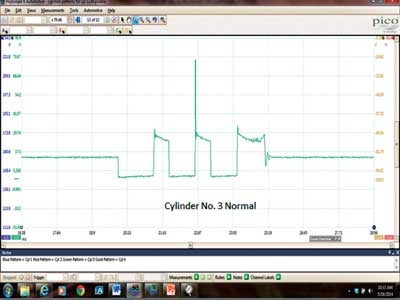

After the above data was obtained, we took a look at the mechanical integrity of the engine. Pico Scope software was used to get data quickly; Figures 5 and 6 show what we obtained.

The mechanical test per the Pico Scope software showed that the mechanical integrity appears to be OK, it is now fair to mention that the cylinder head on bank 1 was sent out to a machine shop to evaluate.

A cranking vacuum test shows some interesting activity. If one were to start at where the ignition event for cylinder no. 7 starts as indicated by the arrow in Figure 6, this is the vacuum pull (intake event) for cylinder no. 5.

The next series of intake events occur in the following order. Please note the aggressive downward spike, this is the vacuum pull for cylinder no. 3. It shows this behavior because the cylinder just prior to it is cylinder no. 1, which is misfiring. Cylinder no. 1 has slowed down due to the misfire activity, when cylinder no. 3 is not its intake event, this cylinder speeds up. If you label the first vacuum pull as no. 5, you would then follow the firing order to label the rest. The sequence would be as follows: 5-4-8-1-3-7-2-6. The generic scan data shows we have good oxygen sensor activity and low fuel trim values. The fuel trim values were +8 for bank 2 and +4 for bank 1. This implies that this may be ignition related.

A review of the ignition system on this vehicle shows it to be a coil-on-plug system. All of the coils on bank 1 were scoped to get an idea of the ignition activity on this bank. Please review Figures 7 and 8.

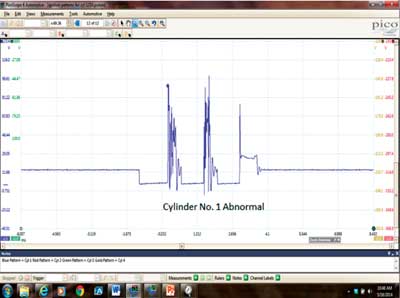

Figure 9 is the picture we obtained for cylinder no. 1 on ignition.

The next step is to swap the coils between cylinders 1 and 3. We swapped the coils and found that there was no change. We then decided to swap the spark plugs between cylinders 1 and 3 and found that the miss followed where we placed the bad spark plug.

The coil connector was checked for a good feed and ground circuit as well. It is not clear per the figures, but on the good coil firing (cylinder no. 3) we have an input voltage of 14.7 volts.

The input voltage for cylinder no. 1 is 12.3 volts; there is a voltage drop in the circuit indicating that additional resistance was in the circuit in addition to the bad spark plug firing.

I then asked the tech to scope the other bank to obtain more information and we found a bad spark plug firing on cylinder no. 5; this had not been identified by the PCM as an issue yet.

The final conclusion that we have drawn on this is to make sure to check feeds and grounds to the coil connectors, be sure to use the correct spark plugs and scope the coil firings to make sure the job is complete.