Only about 1.3 million electric vehicles (EV) are registered in the U.S. While it is not a huge number, it is a growing segment with many opportunities for independent shops. The most common EVs on the road come from Tesla. The Model S, 3, X and Y share similar drivetrains and wheel-end components like the wheel-bearing hub units.

The process of replacing the hub unit on a Tesla is the same as many cars and light trucks. You do not need insulated tools or gloves to replace chassis parts. The only complications come with initial diagnostics and setting modes for service procedures.

Diagnostics

Wheel-bearing noise on a Tesla can be challenging to diagnose. Due to the regenerative braking system, the bearing noise might not change when the brake pedal is depressed. Also, due to the electric motor and drivetrain, bearing noise might not sound like a typical internal combustion vehicle.

Diagnosing bearing noises might require special tools like wireless chassis ears to isolate noises. Running the vehicle on a lift in drive is difficult for a Tesla, and it could activate the traction control systems. Sometimes, the best inspection method is checking for play and measuring for runout and end play with a dial indicator.

Before you work on a Tesla, it is critical to have access to service information. Tesla’s service information website can be found at www.service.teslamotors.com. Starting in May 2022, the individual account has been free. The website has all the procedures to service the brakes and other systems on the vehicle. The site is easy to navigate and contains critical information like torque specs and the procedures to repair most systems. The site also covers all the models.

The most challenging part of servicing a Tesla is the lack of aftermarket scan tools. Tesla cars have an OBDII port above the dead pedal behind a cover. But, this only provides access to the power, ground and BEAN bus. The proprietary connector for diagnostics is typically in the trunk or front trunk.

Prep Work

Before you start removing lug nuts, roll the driver’s-side window down. Why? The upper channel for the window is in the roof rail. When the door is opened, the electric window motor lowers the glass slightly to clear the lip of the seal. If the power is disconnected first or the 12-volt battery goes flat, it can’t lower the window when the door is opened or closed. This could result in shattering the glass. This goes for the other doors on the vehicle as well. In addition, this practice prevents you from getting locked out of the car.

Use the touch screen to disconnect the power and disengage the parking brake. In the service menu, put the car into Tow Mode or Transport Mode. This will disengage the parking brake. You will also have to engage the Jacking Mode for S Models with air suspension to prevent damage to the air bladders.

If you are just replacing the hub unit, you will not need to retract the parking brake mechanism. However, if you replace the brake pads or the rotor, you must actuate the parking brake motor. There are several options to retract the parking brake.

The factory method is to use a special tool that connects to the caliper actuator and reverses the DC power. There are several other non-factory methods to retract the pads, including removing the actuator. Use your best judgment.

The Repair

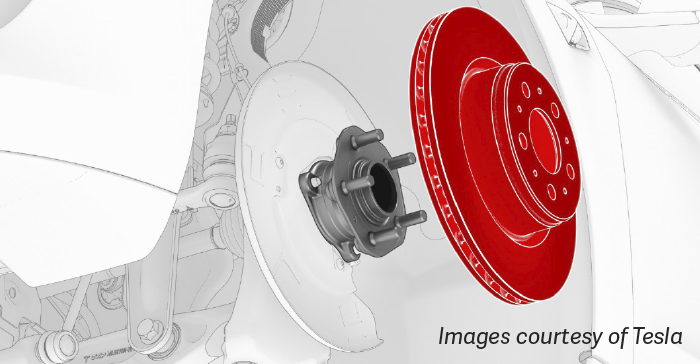

Every Tesla uses wheel-bearing hub units in the front and rear. The unit attaches to the knuckle using four bolts. The hub units use a magnetic encoder ring on the back. The magnets can attract magnetic debris. Check the encoder ring before you button up the job. Debris that is stuck to the ring can cause erratic sensor performance and damage the sensor and encoder ring.

The basics of wheel bearing replacement apply to the Tesla. Make sure the bore and mating surfaces on the knuckle are free from corrosion. Always use a new axle nut and tighten the nut to the correct specifications.

When selecting a new hub unit, consider the performance capabilities and curb weight. Just about every Tesla can achieve a 0-to-60 time of less than five seconds. Also, a dual-motor Model X can weigh 5,390 lbs. This is more than the weight of a new 4×4 Ford F-150 with a 3.5 EcoBoost full-hybrid drivetrain. Even the lightest Tesla models are more than 4,000 lbs. These hub units do not have an easy life. Choosing a low-quality replacement part might result in premature failure.