Wheel bearings are essential components on conventional gasoline-powered vehicles. Wheel bearings keep all four wheels turning efficiently for smooth driving, while also helping to support the weight of the vehicle. In fact, they are just as important, if not more important, when installed on Hybrid Vehicles (HVs), Plug-In Hybrid Vehicles (PHVs) and Electric Vehicles (EVs). We’ll get into that a little later on.

The bottom line is that there are a lot of myths surrounding HVs, PHVs and EVs in our industry. Sometimes it’s hard to filter through those misconceptions and get to what’s true instead. So, let’s take a closer look at wheel bearings for these applications, and why they are even more critical when used on these specialized vehicles.

Similar, but Different

Wheel bearings are designed to withstand tremendous loads while driving. They are extremely strong and durable. But they don’t last forever, and their performance can begin to degrade if they are subjected to harsh impacts or contamination.

But, with few exceptions, there are hardly any differences between the wheel bearings used on gasoline-powered vehicles and EVs. They’re not made out of exotic materials. They are typically very similar, if not exactly the same as the wheel bearings used in conventional gasoline-powered vehicles.

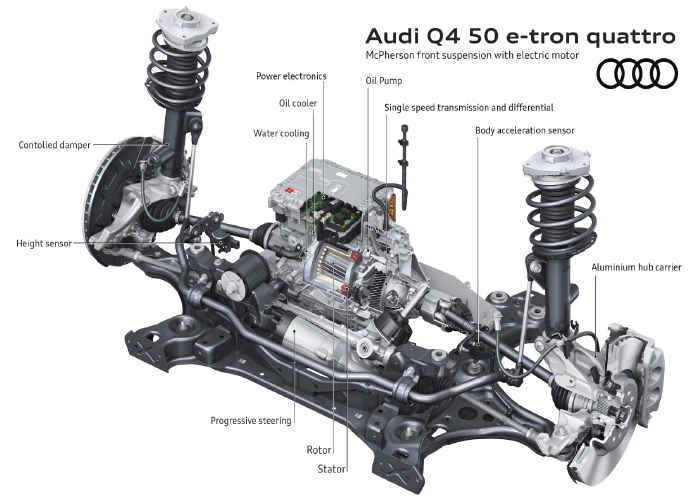

If you look closely at this illustration of the Audi Q4 50 e-tron quattro, you’ll see a number of familiar components. Sure, there’s a large electric motor in the middle of the subframe, but there’s nothing strange or exotic about the wheel bearing, is there?

Quite the opposite, in fact. We zoomed in on the wheel hub to get a better view of the bearing internals. You can clearly see two ball bearing rollers and races, a CV joint and an axle bolt to apply preload. If you can’t see the electric motor in the subframe, you might think you’re looking at a photo from a conventional vehicle, wouldn’t you?

The bottom line here is that the bearings still have the same responsibilities, regardless of what vehicle they’re installed into. They need to keep the wheels turning smoothly and help to support the weight of the vehicle.

Under Load

In many instances, the exact same bearing part number might be installed into a gasoline-powered or EV version of the same vehicle. However, that same bearing will have to work harder on an EV.

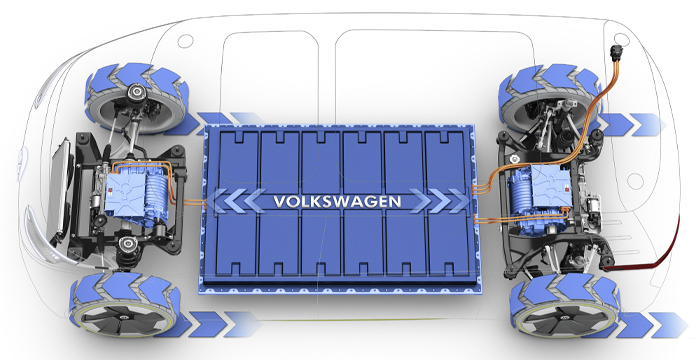

Here’s the simple truth – HVs, PHVs and EVs are heavy. Let’s look at an example of a vehicle that is offered with a gasoline-powered engine and as an EV – the 2019 VW Golf & E-Golf. How do these two vehicles compare? Can you guess which one is heavier? If you guessed the E-Golf, you’re correct!

The VW Golf tips the scales at 2,963 pounds, while the E-Golf weighs in at 3,455 pounds. That’s a difference of 492 pounds! HVs, PHVs and EVs may be more advanced than their gasoline-powered siblings, but they are heavier. Battery packs, electric motors…these components are heavy. Hybrid vehicles have additional components and systems on board to operate the hybrid drive, which also add weight to the vehicle.

Remember that one of the primary jobs of wheel bearings is to help support the weight of the vehicle. So, the wheel bearings that are installed on the E-Golf will have to support an extra 492 pounds of vehicle weight. Keep this in mind whenever servicing one of these vehicles. It’s in your best interest, as well as your customers’, to choose the highest quality bearing possible. It’s safe to say that it will go through a lot more punishment.

Other Factors

When you think of EVs, namely Tesla, you might think of advanced systems such as self-driving and auto emergency braking. EVs are seen by many as being on the cutting edge of safety technology. These systems fall under the umbrella of ADAS, and they are critical to vehicle and occupant safety.

ADAS systems rely heavily on a number of systems and components. This includes brake linings, hoses, the ABS unit, steering components, and of course the wheel bearings. If the vehicle’s lane keep assist needs to steer you back into the lane, a loose ball joint or steering linkage will make that more difficult. If the vehicle starts to skid due to a loss of traction, but a wheel bearing is worn out or the wheel speed sensor inside isn’t producing a high-quality signal, the system may not be able to regain control.

All of these components and more simply must be in top-working order for the ADAS systems to function properly.