By Chris Burton, ALLDATA editor, and Jeff Webster, ALLDATA technical writer

Some Subaru drivers may complain of a knocking noise, which seems to be coming from the engine. This tech tip describes a modification made to the timing belt tensioner bracket to prevent the knocking noise.

On SOHC engines, the shape of the bracket and the size of the two (upper side) installation bolts were changed. On DOHC engines, the shape of the bracket was changed and ribs were added to increase rigidity.

Production Line Change: The new-style tensioner brackets were used in production starting in February 2004.

Affected Vehicles:

Model Body VIN (Starting)

2005 Legacy Sedan 5*200001

Wagon 5*300252

2005 Impreza Sedan 5*500012

Wagon 5*800011

2004 Forester 4*762802

Parts Information:

SOHC 2.5L Engine

Part Name New Part Old Part

Bracket Complete 13156AA052 13156AA051

Bolt (2 Required) (8x55x20) (8x42x22)

800708460 808208330

DOHC 2.0L and 2.5L Engine

Part Name New Part Old Part

Bracket Complete 13156AA062 13156AA061

A countermeasure was made to the timing belt tensioner, which has been incorporated in production since April 5, 2002.

A new heat treatment procedure was used to improve the hardness of the surface at the plunger to prevent poor sealing.

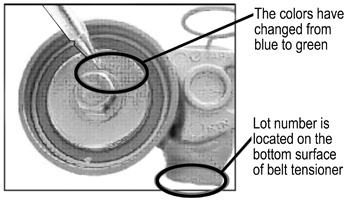

Identification of countermeasure belt tensioner: The color of the paint dot on the pulley bolt was changed from “Blue” to “Green” (see Figure 1). Lot number of belt tensioner: 020402 and after.

Repair Procedure

Identify if the noise is coming from the timing belt tensioner or tensioner bracket when the engine is cold.

1. With the hood raised, listen carefully where the noise is coming from. If the noise can be heard from around the timing belt cover area, there is a possibility that the noise is coming from the timing belt tensioner.

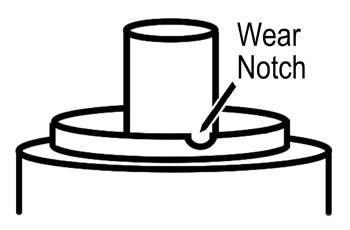

2. Confirm if the noise is coming from the upper portion of the timing belt tensioner by using a stethoscope. If noise can be heard, it’s either coming from the tensioner or bracket. Inspect the belt tensioner; if the cylinder body of the timing belt tensioner has a notch from wear, the tensioner will need to be replaced (see Figure 2).

Caution: Review timing belt and tensioner removal and replacement procedures in OEM manual or ALLDATA Repair, prior to removing tensioner or tensioner brackets.

3. If the engine number is 572570 for SOHC or 572928 for DOHC and after, replace the timing belt tensioner bracket.

4. If the engine number is 572570 for SOHC or 572928 for DOHC and before, check to see if the cylinder body of the timing belt tensioner has a wear notch. If so, replace the timing belt tensioner. If the cylinder body of the timing belt tensioner does not have a wear notch, replace the timing belt tensioner bracket.

5. Verify correct timing of the belt, camshaft and crankshaft after tensioner and/or bracket installation.

6. Test-drive the vehicle to confirm the repair.

Courtesy of ALLDATA.