Editor’s Note: We typically highlight the next generation of young men and women aspiring to enter the industry in the United States. But, when a young engine builder from the Netherlands reached out to us about his Volkswagen VR6 engine, we couldn’t pass up talking to him about his project and how working in automotive in the Netherlands compares to the U.S.

When we heard from Bas Willems, a 20-year-old from the Netherlands, was building a Volkswagen VR6 engine for a 1988 Volkswagen Golf MK2, we had to get the whole story.

Bas Willems lives in Belfeld, Limburg, the Netherlands, and like many engine builders here in the States, he grew up with motorcycles and pretty much everything that runs on gas or diesel.

“When I was just 6 years old, I got my first dirt bike, and ever since then, I was nowhere else to be found than in my dad’s garage,” Willems says. “When I got older, I got more into cars and that’s how it all started.”

That passion led Willems to enroll in an automotive school in Venlo, Limburg, the Netherlands where he is currently finishing his third and final year.

“My studying currently is based on working and getting real-world experience, so that means I only have one school day and work four days in a universal car garage,” Willems says. “There we do every brand on the market. We do things like maintenance on a Volkswagen Golf MK7, but we also do maintenance on an old Cadillac. The classroom portion covers mathematics and automotive lessons. We also have written tests that are all based on what we have done while at work. For instance, after you learn to change brakes or replace a clutch, you have a test on it.”

After graduating, Willems plans to attend for two more years in an effort to get a higher degree in automotive, which isn’t required, but will allow him to earn higher pay and will make finding good work easier.

That is a smart choice considering the engine builder/car mechanic shortage is also a problem seen in the Netherlands, according to Willems. “Too many people would rather choose a job as an office worker because it’s higher paying than a car mechanic, but they don’t realize there are too many office workers right now so they don’t find a job.”

If given the choice of a dream job, Willems says he would be right at home building engines and working on project cars. If that didn’t pan out, he would love to own a garage with a focus on Volkswagen cars and engines.

Fortunately for Willems, he’s already well on his way to achieving his dreams. After school and work hours, he has been hard at work rebuilding a Volkswagen VR6 engine for his 1988 Volkswagen Golf MK2.

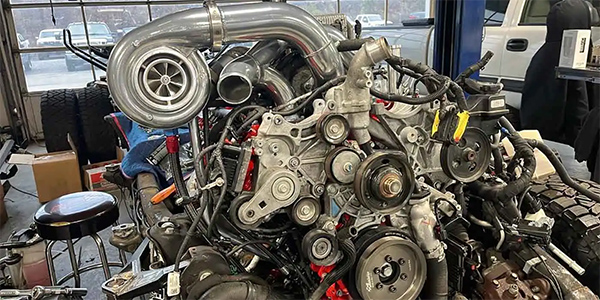

“I decided to build this Volkswagen VR6 engine because I always loved the brand and I thought it would be nice to rebuild an engine that isn’t around a lot anymore,” he says. “The engine is a 2.8L VR6 engine with DOHC. Originally, it isn’t turbocharged, but I’m thinking about making it turbocharged because turbos always give that little extra to the engine.”

The original VR6 engine came from a still-running Golf MK3. Because the engine was still running, Willems knew there wasn’t anything significantly wrong with it. However, before putting the engine in the Golf MK2, he wanted to make sure the engine was 100% like new again.

“I built the engine in my dad’s garage, and I actually had every tool necessary to build it because my dad has his own company working on electric machines,” he says. “The only thing I didn’t do myself was some of the machine work. A guy named Roel, who owns RTS Revisie in the Netherlands, helped me out. I got to know him through my automotive studies.”

To start the build, Willems first stripped the entire engine and inspected every part. He noticed the engine’s cylinders had 0.1mm runout. He also saw some metal in the engine oil, so he took the oil pump apart and found it was damaged, so he replaced it with a new Pierburg oil pump.

“I drilled the cylinders 1mm over the original size and installed new Pierburg pistons, which were 1mm oversized as well,” Willems says. “Then, I rebuilt the cylinder head and put new Swag bearings in the entire engine and used a Swag timing chain. After that, I started to put everything back together. Any old parts I was not sure about I renewed to be sure the engine was 100% new again. The engine got aftermarket pistons, bearings, gaskets and seal rings, oil pump and pan.”

Willems admits he didn’t have a performance goal in mind for this engine build, but it will be chip tuned to crank out more than 200 horsepower. Originally, this engine delivered 174 horsepower.

“If I do decide to add a turbocharger to it, the Volkswagen VR6 engine will gain even more horsepower,” he says. “We will see what the future brings.”

Aside from the engine work on the Volkswagen VR6, Willems’ 1988 Volkswagen Golf MK2 needed some love and attention too.

“The car will be around 1,000kg (2,204 lbs.) so it’s going to be a light car with a lot of power in it!” Willems explains. “The Golf MK2 will be completely re-sprayed and rebuilt with a big brake kit and air ride suspension to keep it lowered.”

The project has made some major progress since Willems first began back in December 2017. However, since he’s only able to devote evenings and weekends to the vast amount of work needed, his expected completion date is summer 2020.

“The engine is completely done now, but at the moment I’m rebuilding the gearbox and the car, so there is still a lot to do,” he says.

Despite still having work to do, he’s already thinking about what his next project could be.

“When I’m done with this build, I would like to build a Volkswagen Caddy MK1 with a turbocharged R32 engine and a sequential gearbox,” he says. “First I need to finish this project car and refill my bank account! But one day there is going to be a Caddy MK1 R32 in my garage!”

The future seems bright for Bas Willems and his engine building endeavors.

For more on Bas’ Volkswagen VR6 engine build or the Volkswagen Golf MK2 car, follow the progress on his Instagram at @vr6_mk2_project.

This story was written in collaboration with our sister publication, Engine Builder. Visit Engine Builder at enginebuildermag.com.