Courtesy of Engine Builder by Evan Laux

Often times when we interview diesel builders at race events, we get a lot of “it’s nothing much,” or “it’s a pretty simple build.” We like to think people are being modest, because some of the stuff we see is anything but ordinary. Earlier this year at the Ultimate Callout Challenge, we had the privilege or making a new acquaintance out at the track – one Dan Snyder of Snyder Performance Engineering (SPE) Motorsport.

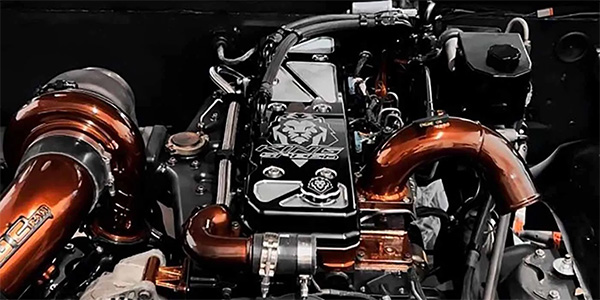

The Latrobe, PA-based shop, just east of Pittsburgh, states on its website that it takes a “mom and pop approach to business” that allows the shop to focus on the quality of its products, which are manufactured in-house. SPE does everything from air-intake systems and fuel systems, to superchargers, turbos, engine components, and transmissions primarily for F-series trucks and Mustangs. SPE also has a full fabrication shop where they build chassis, roll cages and the like for drag racing cars.

Since Powerstrokes are such a big part of the business, building a diesel drag car was almost like a “science project,” as Snyder describes it. They began work on it in 2015 and have constantly been evolving and upgrading the build.

“The 6.4L and 6.0L really kind of gave Ford a bad name in the diesel world,” Snyder says. “Coincidentally, I was working for Ford when the 6.7L came out and of the engineers told me this new platform would fix a lot of the problems from the other ones, including the head gasket stuff. I hopped on that quick. As much as we can, we use factory parts, and the car still has a 4R100 truck transmission. Not only does it help us sell things, but it backs up the idea that I could have that in my vehicle.”

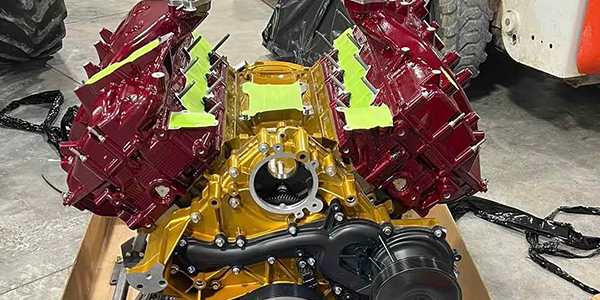

The engine is a factory block, crank, and ported heads, but there are a few performance additions that make it competent on the track. It’s got Carrillo rods, modified MAHLE cast pistons, a custom ground Colt camshaft, and Manton pushrods.