Bramble Energy recently published a whitepaper that the company says identifies a path to creating the world’s lowest-cost fuel cell. The whitepaper reveals Bramble Energy’s plan to create a $100 per kilowatt stack achievable today – ten times cheaper than current traditional fuel cell costs – and has identified the company could reach as low as $60 as a result of scale.

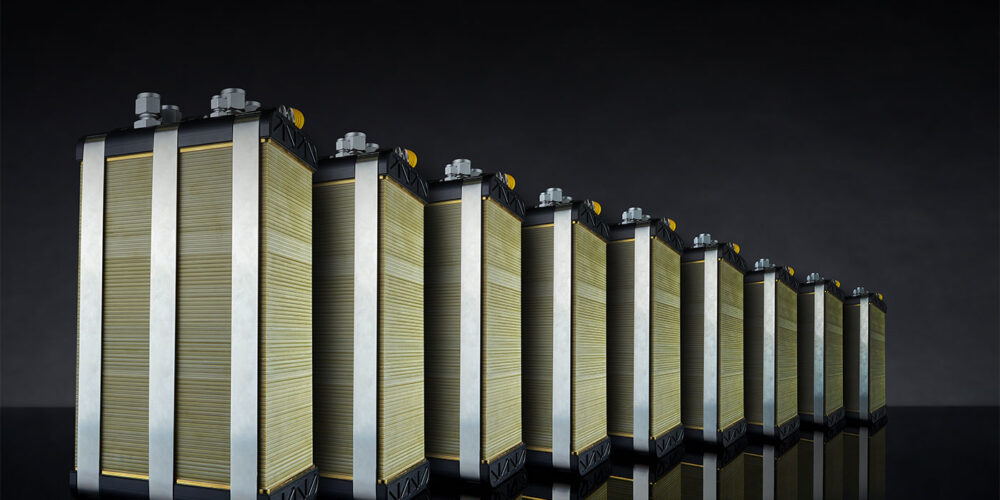

The paper presents Bramble Energy’s patented printed circuit board (PCB) fuel cell technology. Currently, in early phase testing and in-work through its UK supply chain, short stack testing of this technology will be conducted in Q4 2023 after further core module optimization, with full stack testing expected in Q2 2024, the company says. The whitepaper details overcoming the primary challenge of reducing the cost of fuel cells with Bramble leveraging standardised PCB materials and an existing manufacturing route, eliminating the need for capital investments.

Unlike traditional fuel cell technologies, Bramble says its PCB-based approach allows for high-volume production within existing facilities. The throughput of a UK prototyping PCB facility is in the region of 250 panels per day. Larger facilities will typically handle 25,000 panels per day. High-volume facilities also work with larger panel sizes, which are more cost-effective and allow further freedom of design. PCB factories worldwide adhere to manufacturing standards such as ISO9001, ensuring consistent quality and production capacity.

Printed circuit boards are used in various applications from mobile phones to televisions and laptops, with a global manufacturing base worth over $70 billion annually, according to the company.

The core substrate of Bramble’s PCB fuel cell is a standard PCB laminate, which serves as a bipolar plate, providing structural integrity and fulfilling all typical and complex fuel cell functional roles including gasketing, current collection, sealing and more.