This article is courtesy of Engine Builder.

Car enthusiasts often have a field day when naming their creations. A lot of heart, time and character go into a specific build, and a good name serves as a way to symbolize the journey as a whole.

To Travis Goza, the name behind his lifted ‘77 Chevy square body pickup has added significance, in a unique way. Goza bought the truck in high school in 1999 from his father’s friend, tore it down to a bare frame, and rebuilt it to be a sled puller. A lot of money and time were put into the truck, making it an important part of his life. So much so that Goza and his wife Jessica decided to take the truck on their honeymoon.

Ironically, the truck broke down a day after their wedding. Jessica started jokingly calling it “Wasted Wages.” The name stuck and sometime later, Travis and Jessica began doing Cummins conversions for customers in their community and named their shop Wasted Wages Diesel Performance.

“We still operate at a mostly small level,” Goza says. “It’s pretty much full-time for my wife, but part-time for me because I still run around in a field truck working on heavy equipment.”

Wasted Wages, located in Winston, OR, completes a few conversions a year for customers, but mainly focuses on performance upgrades like turbo and transmission work. The shop is also open on the weekend, allowing for businesses to service their trucks outside of the busy work week.

The shop has a strong following and customer base despite being located in a fairly small town. Many of Goza’s customers began coming to the shop after seeing his truck at car shows with the logo displayed prominently on the side with the ‘s’ in wasted changed to a dollar sign for extra flare.

“A lot of our customers come here from word of mouth,” Goza says. “We don’t really do any advertising.”

Goza says that passion fuels the industry, and that’s no more apparent than in his old ‘77 Chevy. Throughout the years, he went through a variety of gas engines in the truck before eventually getting irritated and deciding a Cummins would solve his problems.

“When I was in high school, we just had a little small block Chevy in it,” he says. “I ran that for a while, built the small block 400, and then I built the 496 big block for even more power – they never really satisfied me though. The last motor in it pissed me off, so I sold it real quick and decided I’d throw a Cummins in it.”

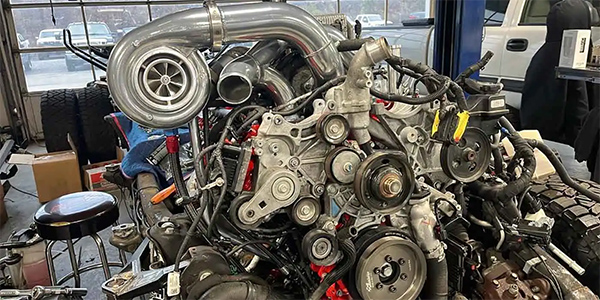

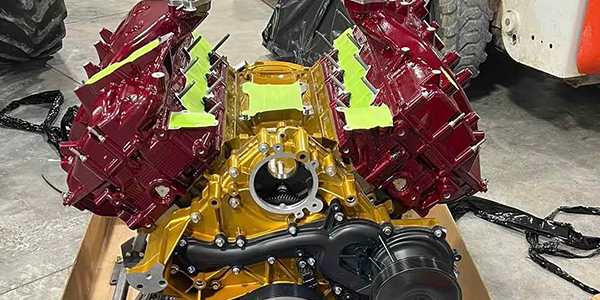

Goza sourced the B-series Cummins from an equipment yard and sent it out to be decked and sleeved. An Industrial Injection Gorilla Girdle was added to the block to stabilize the lower end and allow for higher horsepower. Mahle pistons and Hamilton cylinder heads both help to keep temperatures and exhaust low.

Right now, it’s running a custom-ground camshaft from Scheid Diesel, which Goza thought would be best for the sled-pulling application. ARP main studs, Carrillo rods and roller rockers were also used. Billet aluminum tappet valve covers were built by Keating Machine and the manifold is from Steed Speed.

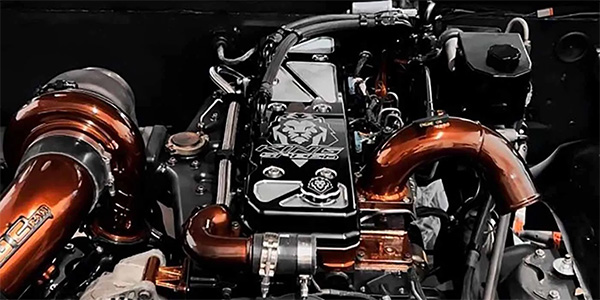

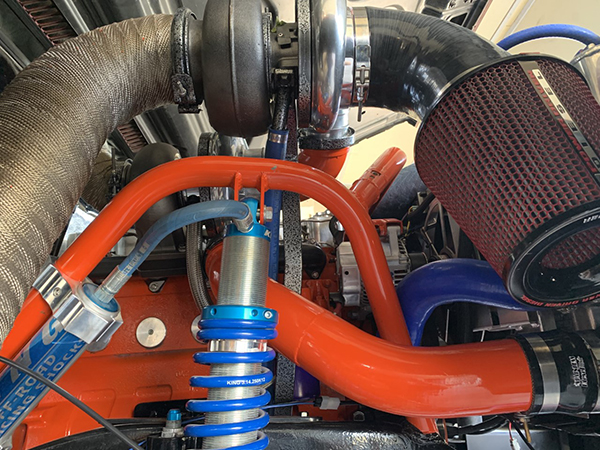

The Cummins also features a compound turbo system, which consists of a high-pressure Bullseye S472 charger and a Borg Warner S480 for the low-pressure charger. Shield Diesel also provided dual-feed injectors and a 14mm sled-pulling injection pump.

“Back when we had our bigger turbos on it, that truck made a little over 1,500 horsepower to the wheels,” Goza says. “That was with a better set of compound turbos on it. Now, we’re actually running a smaller set of compounds on it, trying to get them to spool a little better on the street.”

With the current turbo system, the engine has enough air to support around 1,200 horsepower before it runs out of air. The change of setup happened after Goza slowly began using the truck less for sled-pulls and more for casual driving and car show attendances.

“You get tired of it after a while,” he admits. “You drive three, four hours just to pull once then drive the same three, four hours home, and spend a bunch of money in the process.”

The biggest roadblock for the engine was that it’s a low compression, 12-valve motor made to make a lot of horsepower. Goza says the biggest problem he has to deal with is cold weather, since its low compression and was originally built as a competition engine.

Even though there’s drawbacks to the high-power engine, Wasted Wages is another example of the power and efficiency a Cummins truck can deliver.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].