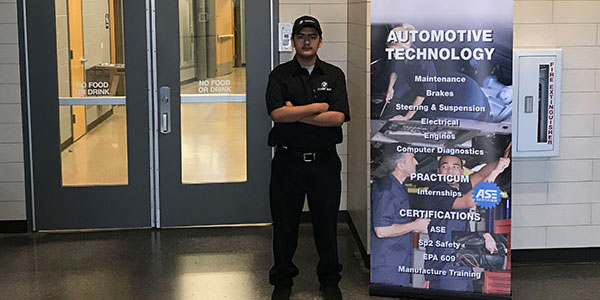

JR Arellano Ocampo is a senior in Automotive Technology at Lewisville School District’s Technology Exploration Career Center East in Lewisville, Texas. He’s already completed both the Auto Tech 1 and Auto Tech 2 programs, has earned multiple ASE certifications and has a paid internship at Classic BMW in Plano.

He has been named the January 2021 Student of The Month by Continental Belts & Hose and Tomorrow’s Technician.

What is it that attracted you to the automotive program at TECC East?

Ever since I was a little kid, I’ve been fascinated by cars. My father had a couple of nice cars and I always was interested in getting my hands dirty on them. I remember watching Transformers and I saw the Camaro that had just been brought back; that’s when I knew this is what I like.

In seventh grade, they brought us through the school here, and I saw some students working on the vehicles. That really got me interested as something I would like to do in high school.

My first vehicle I ever had was a Nissan Murano. I brought it here in the shop to Mr. Emery and we did an oil change and a few other things. And then I sold that one, got a BMW and started doing a couple mods. It was fun. I like working inside the engine bay or under the car.

It helps you learn how a shop actually works – it’s really immersive. What they’ve done here, Mr. Emery and Mr. Dahlgren, they help us know the basics. And sometimes, even more than the basics of the automotive industry. We have a lot of tools like multi-meters, ratchets, torque wrenches, impacts, lifts. They teach brake service, tire mounting and balancing, alignments… They really take you through the whole automotive industry.

Tell us about your internship with Classic BMW in Plano, Texas.

It’s really great for me. All the people there are pretty awesome. I like seeing how the actual work environment is, how the shop is laid out, how everything works out, everything that goes from service advisers to the foreman, the shop manager down to the tech.

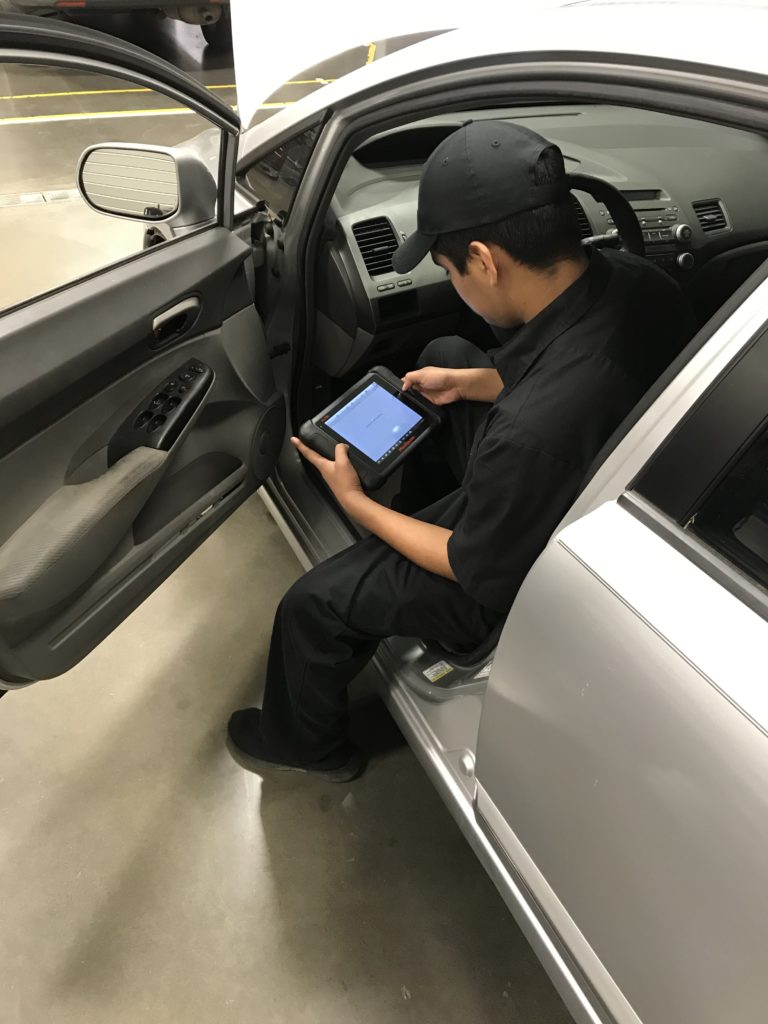

I really like working on vehicles. Right now I’m an hourly, so I’ll do what they call the QCs. Basically, I inspect cars, making sure they’re good on tire pressure, washer fluid, coolant. I’ll make sure, if they have a repair, that the problem is not occurring again or help figure out what the problem really is that we need to solve.

With your internship, you have more hands-on opportunities than some other students may get. Are you able to be a leader or a mentor to other students in the classroom?

Most of the time I’m in the dealership, out in the industry, so I’m not here, but about every nine weeks, I come back here just to check and make sure everything’s fine with the teacher and me. The students who are working on a car often need some help. The teachers will let us help them out or offer guidance about something, if they need our assistance.

The times I’ve been here, I’ve been able to help them out with a couple of things that I knew we we had faced in the past, I really like helping people, especially whenever I know something that helps how it works and how it can help them fix it.

What are your future plans?

I graduate in May, after which I plan on going to Universal Technical Institute for a nine-month course in the automotive industry. After that, I’m planning on going through the STEP program for BMW.

I really like working on BMWs and the idea of becoming a master technician. I’ve seen a couple of the students who have gone through this program, and I’ve seen them go through the STEP program. It really fascinates me how far you can get in the automotive industry.

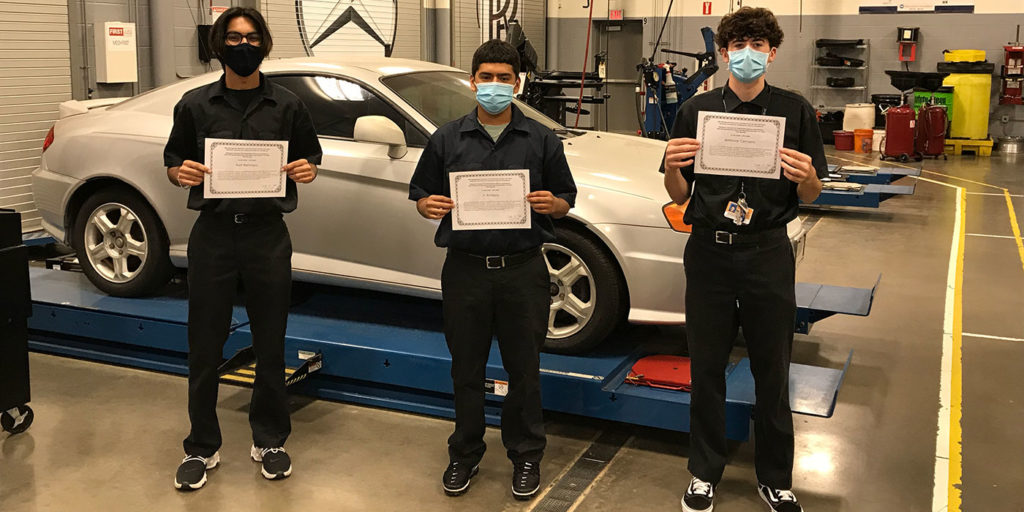

JR’s instructor, Doug Emery, says “JR has completed both the Auto Tech I, Auto Tech II and is currently in our practicum program. He has earned multiple Entry-Level ASE certifications, EPA 609 certification, and multiple NC3/Snap-on certifications. JR’s hard work in Auto I and Auto II paid off, currently he has a paid internship at Classic BMW. Instead of coming to class, JR goes to the BMW dealership where he works with a master BMW technician and learns the ins and outs of working on BMWs.”

Emery says JR’s modesty shouldn’t distract from his ability. “Usually, I make the advanced students talk to the seventh graders when they come to visit. Because one of the things students must do for the practicum courses, is to interview for all those positions. They’re not guaranteed a position. They need to get used to talking in front of other people – I always tell them, if you can talk to a group of kids you’ll be fine in an interview with an adult.

This’ll be the hardest thing they do, to talk to 20 or 30 seventh graders and keep them interested in learning about auto tech.

To nominate a student for consideration as a Continental Belts and Hose Student of the Month, click here.