Tenneco is putting its 100-plus years of powertrain expertise in improving vehicle fuel efficiency and reducing emissions to work to explore synthetic fuels (e-fuels), a viable near-term solution to further maximize the efficiency and minimize the carbon footprint of internal combustion engines (ICE). Tenneco’s Powertrain business group is partnering with key academic and industry experts to examine the technical possibilities and commercial feasibility of synthetic fuels as a key technology to help the industry transition to climate-neutral transportation. This collaborative effort is referred to as the NAMOSYN project.

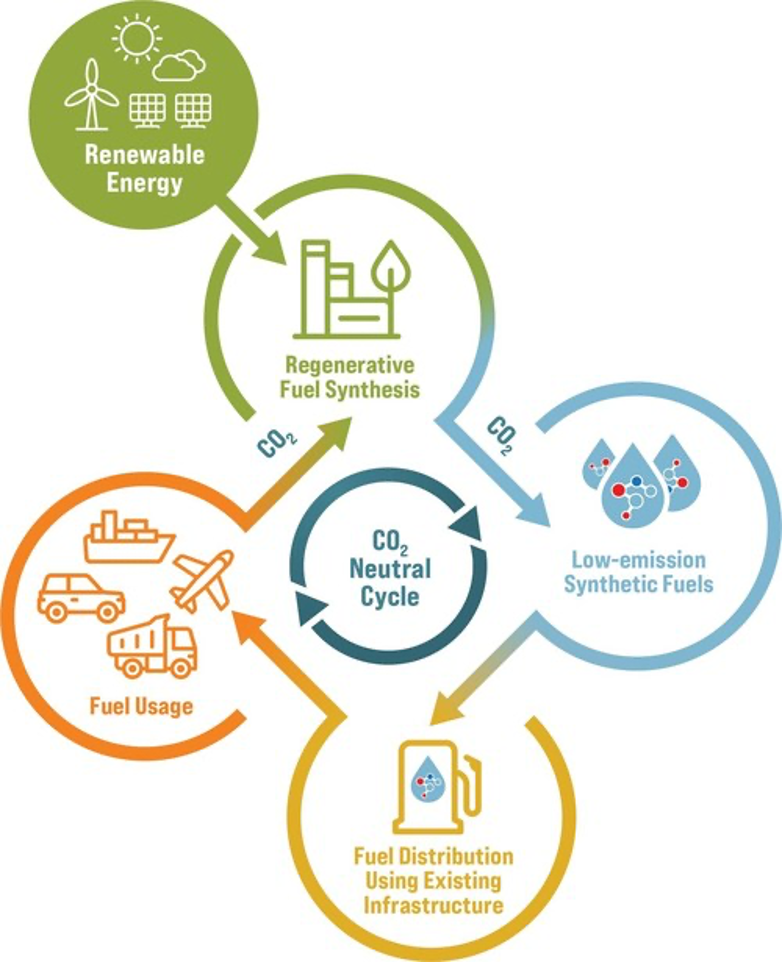

Viable near-term solution for climate-neutral mobility: Synthetic fuels (e-fuels) can play an important role in achieving climate-neutral mobility. By using renewable energy sources, such as solar or wind power, a closed CO2 cycle is created when viewed from a holistic “well-to-wheel” perspective. Only as much CO2 will be emitted as was originally extracted from the air to produce these synthetic fuels.

Synthetic fuels for passenger vehicles, commercial trucks or even marine applications can play an important role in achieving a near zero emissions mobility, by using renewable energy sources, such as solar or wind power, to create a closed CO2 cycle when viewed from a holistic “well-to-wheel” perspective. A climate-neutral alternative to petroleum-based fuels, they also offer the potential for significantly reduced overall emissions, allowing Tenneco’s Clean Air experts to better manage any remaining pollutants through the aftertreatment process.

Synthetically produced, climate-neutral e-fuels can be used in today’s gasoline and diesel engines with only minor modifications for most of e-fuels and in blends with conventional fuels. This makes them particularly suitable for vehicles with traditional ICE as well as alternative powertrains such as hybrids. Additionally, the e-fuels can be made available to consumers by using mostly the existing, well-developed fuel distribution and filling station infrastructure with only minor adjustments, making the technology even more appealing as a near-term, fast-to-market solution.

“It is widely acknowledged that solutions must be found to reduce a vehicle’s carbon footprint. In addition to light vehicles, internal combustion engines are also popular in trucks, marine propulsion, construction equipment and agricultural machinery,” explains Dr. Steffen Hoppe, director Global Technology for piston rings and cylinder liners at Tenneco´s Powertrain business group in Burscheid, Germany. “Regardless of the differing opinions when full electrification will be reached, any technology that we can adopt now that enables a significant reduction in CO2emissions, or even CO2-neutral operation of the IC engine, will be an essential contributor to the timely achievement of climate targets. We are excited to be an active part in the development of this type of technology.”

Research project NAMOSYN – sustainable mobility with synthetic fuels

To help further the understanding of synthetic fuel technology, Tenneco has joined a consortium of automotive suppliers, vehicle and fuel manufacturers, chemical companies, Fraunhofer institutes and universities as part of the NAMOSYN project (www.namosyn.de), which is supported by the German Federal Ministry of Education and Research. The effort is scheduled to run through March 2022.

Taking advantage of the site´s 19 fully automated and monitored high-performance test cells, Tenneco´s Burscheid, Germany team is investigating how innovative piston ring designs in combination with synthetic fuels can be used to develop mobility concepts with lowest emissions, the target being zero emissions impact.

The NAMOSYN project also serves to develop cost-effective and energy efficient manufacturing processes for synthetic fuels and to test them in internal combustion engines. In the diesel sector, this notably concerns the group of oxymethylene ethers (OME); for gasoline engines, the focus is on dimethyl carbonate (DMC) and methyl formate (MeFo). In parallel, a wide range of different material configurations are tested to determine the optimum synthesis and composition over/across the entire process chain.

Initial results of the current research are promising. “By using synthetic fuels in internal combustion engines, we have been able to demonstrate a reduction of 50 percent or more in all nitrogen oxide, carbon monoxide and particle emissions,” explains Bartosch Gadomski, Senior Test Engineer and Project Manager NAMOSYN at Tenneco. “In order to actively support the timely market introduction of synthetic fuels as far as possible, we also test mixtures or blends of conventional fuels and e-fuels under real conditions on our engine test benches.”

In the final step, these test units are installed in test vehicles and examined for driving behavior and emissions. In addition, the compatibility of the e-fuels with the existing infrastructure for fuels, such as tank trucks or filling station systems, is evaluated and solution concepts for new requirements are developed.

Synthetic fuels as an important component in the mix of technology solutions for sustainable mobility

To minimize climate impacting emissions, synthetic fuels are preferably produced using electricity that is generated from carbon neutral renewable sources. In case of OME and DMC, synthetic fuels as methanol, ethanol, MTG Fischer Tropsch Diesel, and others can be produced with hydrogen by electrolysis – also generated by using surplus fluctuations in renewable electricity – and carbon dioxide (CO2), which comes from industrial waste gases or from the air. The next process step converts the syn gas to synthetic fuels. This method ensures that a closed CO2 cycle is created: in a holistic approach (“well-to-wheel”), the vehicle later emits only as much CO2 as was originally extracted from the air to produce these synthetic fuels.

E-fuels should have favorable combustion properties so that an ICE can be operated as efficiently as possible and local pollutant emissions can be kept low. One of the advantages of synthetic fuels is that their composition can be developed specifically to meet the needs and different performance requirements of their applications. In order to achieve the highest possible efficiency, e.g. via so-called lean combustion, adjustments to engine control and hardware are necessary, depending on the engine type.

The aim of research at Tenneco is to achieve the highest possible efficiency of internal combustion engines as well as the greatest possible reduction of raw emissions, especially in terms of particulate emissions.

“The development of new vehicles with ICE powertrains must pursue the goal that these drives will be climate-neutral. We need synthetic fuels and hydrogen from sustainable energy sources in order to achieve the climate targets for future cars and trucks, but also for the millions of existing vehicles powered by an internal combustion engine,” concludes Hoppe.