Question: Is there a mileage or time requirement for oxygen sensor replacement?

Question: Is there a mileage or time requirement for oxygen sensor replacement?

Answer: The simple answer is “No.” Oxygen sensors were first used for fuel trim and emissions in the late 1970s and into the mid 1990s. A single sensor was installed into the exhaust stream to modify fuel delivery and maintain catalytic converter efficiency.

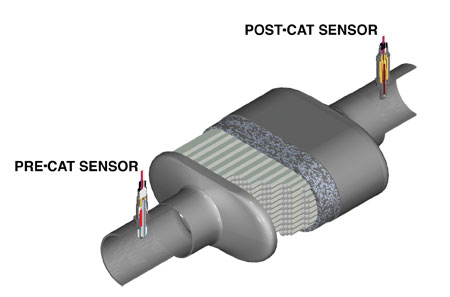

Beginning January 1, 1996, OBD II became a global requirement. The pre- and post-catalytic converter

oxygen sensors are part of these requirements. The pre-catalytic converter oxygen sensor is used for fuel trim and the post-catalytic converter oxygen sensor is used to monitor converter efficiency.

The current Federal OBD II warranty period for an oxygen sensor is two years or 24,000 miles, whichever comes first, but with proper care and the right fuel diet, the oxygen sensor should be a maintenance-free

emissions system component.

Knowing how the oxygen sensor operates and what makes up the exhaust gasses that flow past the sensors and through the catalytic converter can help in determining when to replace and prevent future problems.

Question: How long should an oxygen sensor last?

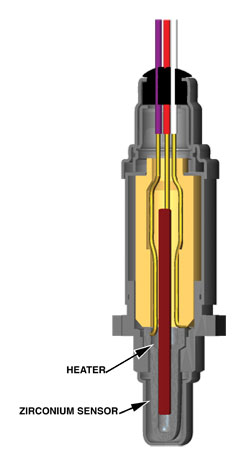

Answer: An oxygen sensor should outlast the vehicle emissions warranty. Manufacturers recommend that the unheated type used from the late 1970s to the 1990s be inspected every 30,000 miles and the heated type used from the early 1980s to the mid 1990s be inspected every 60,000 miles. Manufacturers recommend for current generation of sensors starting in the mid 1990s should be inspected every 100,00 miles.

In fact, with proper powertrain maintenance, it is possible for the sensor to last the life of the vehicle, which could be in excess of 250,000 miles.

Question: Do oxygen sensors degrade over a period of time? And if so, what causes degradation of the component?

Question: Do oxygen sensors degrade over a period of time? And if so, what causes degradation of the component?

Answer: Yes. The reason is when silicon was an ingredient in RTV and coolant, the silicon could cause the sensor to rapidly degrade. It was referred to as silicon poisoning.

Today fuel and maintenance are two major contributors to a sensor’s degradation. Gasoline and diesel fuel are refined products from crude oil. The refined product contains a mixture of different hydrocarbons including olefins, benzene and the chemical element sulfur.

Sulfur is a chemical element that occurs naturally in crude oil. The refining process reduces the concentration of sulfur in the gasoline. Sulfur can cause the degradation of an oxygen sensor and the concentration of the sulfur in the gasoline will determine the rate at which the sensor will degrade.

Gasoline with a content of 1,000 parts per million (ppm) has been shown to cause accelerated degradation resulting in the illumination of a service soon light. To put a 1,000 ppm in perspective, if you have a thousand gallons of gasoline, it will have one gallon of sulfur. Gasoline also contains other added ingredients.

The following are ingredient descriptions for gasoline additives: Octane enhancers, antioxidants, metal deactivators, ignition controllers, icing inhibitors, detergents and corrosion inhibitors.

One of these ingredients is MBTE (methyl tertiary-butyl ether). It was originally introduced in the late 1970s as an octane enhancer to replace Tetra Ethyl Lead for catalytic converter-equipped vehicles. It is also used as an oxygenate. MBTE has little or no affect the operation of the oxygen sensor introduced in the 1980s. But, when Congress passed the Clean Air Act Amendments of 1990, MTBE levels in the new

“reformulated gasoline” for certain areas of the country increased. This has affected the life of some newer

oxygen sensors.

Alcohol in the form of methanol and ethanol are oxygenates that are added to gasoline. E85 fuel is a mixture of 85% ethanol and 15% gasoline. E85 will burn cleaner and produce less degradation of the

oxygen sensor. But, it is a compromise in fuel economy, because there is less energy in a gallon of E85 than a gallon of gasoline. Methanol is a fuel associated with racing. It is a hazardous material and poisonous which limits its use as a commercial fuel.

Motor oil contains phosphorous which can also cause the degradation of the sensor when excessive oil vapor is introduced through crankcase ventilation. So one of the components that should be recommended after a oxygen sensor replacement is the PCV valve.

Question: Does overall engine maintenance affect the life of an oxygen sensor?

Answer: Yes, in fact, an important maintenance item is the oil change. The reasoning is that Positive Crankcase Ventilation (PCV) can contribute the degradation of the oxygen sensor because vapors from contaminated oil in the crankcase can shorten the O2 sensor’s life. This is a reason why you should use the manufacturer’s recommended oil for the vehicle since all petroleum products will contain sulfur.

Question: When does an oxygen sensor need to be replaced?

Question: When does an oxygen sensor need to be replaced?

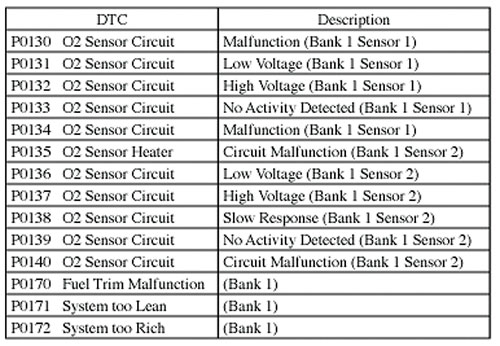

Answer: The service engine soon light will come on and a diagnostic trouble code(s) will be stored. Chart 1 is a partial list of Diagnostic Trouble Codes (DTC) for the pre (Sensor 1) and post (Sensor 2) sensors. If the sensor is damaged or not responding, it should be replaced. There are DTCs for V type engines (Bank 1 and 2) and a third sensor.

There may be multiple codes stored for a sensor. A fuel delivery malfunction can be the reason for an oxygen sensor to fail. A fuel injector malfunction could be the root cause for the sensor failure. Just replacing the

sensor may not be a long-term solution.

Question: Can an oxygen sensor affect engine performance and fuel economy?

Answer: Yes. The oxygen sensor drives fuel trim and fuel trim is all about fuel economy. Good fuel and good maintenance are key to long component life and fuel economy.