Delphi Product & Service Solutions is introducing an industry-wide program aimed at educating technicians, DIYers and consumers on the importance of properly cleaning a vehicle’s gas tank prior to installing a new fuel pump.

Clean the Tank for Optimal Fuel Pump Life

Most fuel pump and module warranty issues are linked to debris or contamination in the fuel tank that may have accumulated over vehicle use, or during the removal and replacement procedure. Fine particulate contamination can clog the strainer causing high electrical demand on the fuel pump, and if ingested, can result in premature wear within the pumping section. Both failure modes result in reduced performance, premature failure, or at worst case, a walk home. Fuel pumps and modules may be returned due to installers not cleaning the gas tank properly, causing warranty costs to skyrocket.

The vehicle’s original fuel pump was installed into a clean tank, so to ensure the same level of performance, the new pump should go into a clean tank as well. An industry research study conducted by IMR Test Labs indicated that only 18 percent of technicians perform the correct fuel pump replacement procedure correctly by thoroughly cleaning the fuel tank, fuel filler and strainer if needed. That would indicate a full 82 percent of aftermarket fuel pumps purchased are being installed into tanks that are potentially contaminated.

Recently launched as part of the “Clean the Tank’”program, Delphi now offers a new fuel tank cleaning kit designed to make the job of replacing the fuel pump easier for technicians and enable them to clean the tank more safely and effectively. The kit, which includes cleaning solution, gloves and a lint-free cloth, provides a low-suds cleaning solution specifically designed to allow easy treatment and rinsing of fuel tanks up to 40 gallons in size.

“Clean the Tank” is a multifaceted campaign, endorsed by the Car Care Council, providing independent research information on proper fuel pump maintenance; step-by-step fuel pump installation instructions in English, Spanish and French; a 10-step instructional infographic; how-to videos; warranty training tools; and accompanying marketing collateral – all designed in an effort to help the aftermarket industry reduce fuel pump warranty costs, product returns and “protect the pump.”

Delphi Holds Independent Tests of Fuel Pumps Against Competition

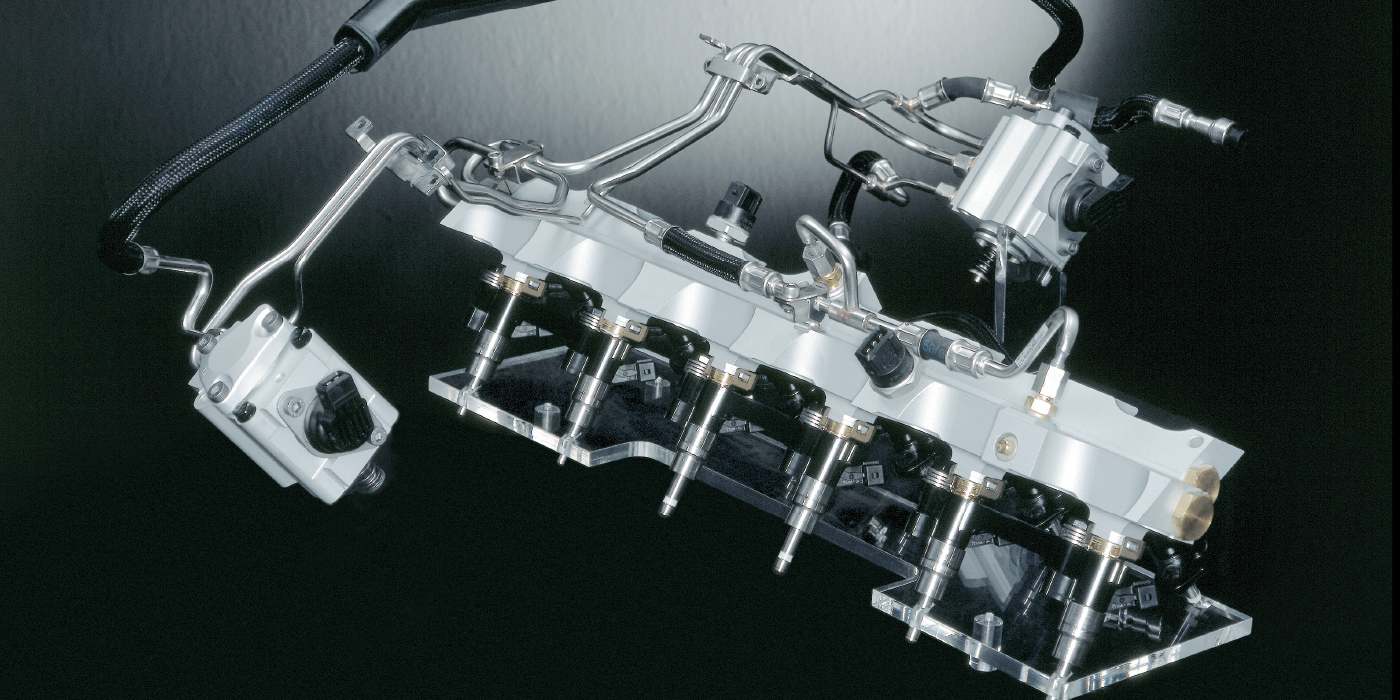

In addition to the importance of doing the repair right, it’s also important to choose quality parts with each repair. Delphi recently commissioned an independent durability test of its fuel pump as measured against the company’s three largest competitors. The goal was to see how long the pumps would perform before they failed. Of those tested, Delphi says its pump was the only one that lasted the duration of the test.

“We’re proud of this industry initiative and our testing results,” said Chad Smith, regional vice president, Delphi Product & Service Solutions. “We’re committed to helping our customers build their businesses by offering their customers high-quality parts and the information to do the repair right.”