The following are various engine technology advances to the the Mazda 3 and 6 models.

The following are various engine technology advances to the the Mazda 3 and 6 models.

2003:

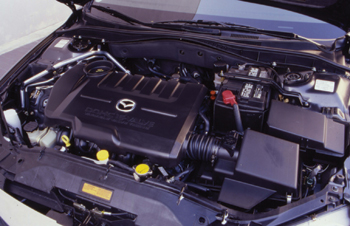

When introduced in 2003, the MAZDA6i was powered by a 2.3L four-cylinder, 16-valve I-4 engine, (shown here) that produced 160 hp and 155 lb.-ft. of torque. The MAZDA6s was equipped with a 3.0L V6, producing 220 hp and 192 lb.-ft. of torque.

Both the 3.0L 24-valve V6 and the 2.3L 16-valve I-4 feature DOHC valvetrains with continuously variable intake valve timing (VVT). This technology provides the ability to tune the engine for smooth running at low speeds and extra power at high rpm. In both MAZDA6 engines, VVT operation is continuous between minimum and maximum set points to achieve optimum performance throughout the engine’s entire operating range.

2005:

MAZDA3’s engine lineup is comprised of a 2.0L and 2.3L powerplant. Each engine is an MZR in-line, four-cylinder unit, offering linear power, low fuel consumption and extremely low emission levels.

In order to isolate passengers from Noise, Vibration and Harshness (NVH), Mazda engineers paid considerable attention to developing a stiff drivetrain. The 2.3L has an all-aluminum construction, which allows for a lightweight yet strong engine block. An advanced deep-skirt block design also aids transmission coupling stiffness.

Through the use of lightweight pistons and connecting rods, engineers were able to eliminate a primary cause of NVH instead of simply adding more sound-deadening material to the chassis.

2009 4-CYL:

In 2009, a new 2.5L 4-cyl engine is available for the MAZDA6 with 170 hp at 6,000 rpm. Advanced features include chain-driven dual overhead camshafts, four valves per cylinder, counter-rotating balance shafts located in the oil pan, and aluminum block and head construction to save weight. The crankshaft is forged steel for utmost durability. Forged powder-metal connecting rods minimize reciprocating weight.

Variable intake valve timing yields a smooth idle and low emissions, and an injection-molded, nylon-reinforced-plastic intake manifold provides smooth internal passages with minimal weight.

Fuel is delivered to the intake ports by an electronically controlled sequential injection system. Ignition coils are modular units positioned directly above the spark plugs. Shim-less bucket tappets require no maintenance.

Light-weight pistons are coated with a special anti-friction compound and fitted with low-tension rings for improved gas mileage.

Several features designed especially for maximum power in the new MAZDA6i application include a new cylinder head with improved intake and exhaust flow, a low-restriction exhaust manifold, and a two-mode intake manifold with a center entry and an electronically controlled throttle body.

To minimize noise and vibration, the damper at the forward end of the crankshaft is equipped with two tuned masses. At the output end, a new flexible flywheel also diminishes NVH.

2009 Mazda V6:

The MAZDA6 was available with a 60° 3.7L V6 engine. Designated MZI, and developed for the 2008 North American Truck of the Year-winning CX-9 model, the engine was then fitted to the 2009 MAZDA6.

The list of advanced features includes light and stiff aluminum construction for the block and cylinder heads, a forged-steel crankshaft with induction-hardened journals and variable intake-valve timing.

Dual overhead camshafts are chain-driven and equipped with maintenance-free direct-acting bucket tappets.

Cast-in iron cylinder liners provide a dependable bore surface.

The intake manifold is injection-molded nylon-reinforced plastic to save weight. Two close-coupled catalytic converters minimize the time required following a cold start for the emission controls to reach full effectiveness.

A dual exhaust system provides low restriction for excellent high-rpm power.

A dual exhaust system provides low restriction for excellent high-rpm power.

To achieve best-in-class smoothness and quietness, the MAZDA6s’ 3.7L V6’s crankshaft has a full complement of counter-weights and a dual-mass damper. The aluminum cylinder-head covers are rubber isolated to minimize the amount of radiated valvetrain noise.

2010:

Mazda’s MZR engine family has become more advanced. As before, there are two distinct MZR four-cylinder engines available in the MAZDA3. The MAZDA3i models are fitted with the MZR 2.0L engine that features a compact and light aluminum block and head construction with two chain-driven overhead camshafts operating four valves per cylinder.

Variable intake valve timing provides robust low-rpm performance with strong high rpm pull, all the way to the 6500 rpm redline. A light-weight nylon-reinforced intake manifold offers dual-mode flexibility with runner lengths ideally suited to both low- and high-rpm operation, and a new front-mounted air pickup system feeds the 2.0L engine cooler air for combustion.

Variable intake valve timing provides robust low-rpm performance with strong high rpm pull, all the way to the 6500 rpm redline. A light-weight nylon-reinforced intake manifold offers dual-mode flexibility with runner lengths ideally suited to both low- and high-rpm operation, and a new front-mounted air pickup system feeds the 2.0L engine cooler air for combustion.

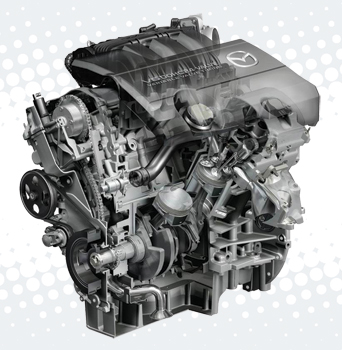

MAZDA3s models benefit with a move from 2.3 to 2.5 liters of displacement. (This new engine — shown above — is similar in most details to that found in the 2009 MAZDA6i.)

Changes from the previous 2.3L unit include a fatter bore and a longer stroke packed into a cylinder block with unchanged external dimensions by using cylinder-bore liners made of a steel-molybdenum alloy offering strength and stiffness increases of 30%.

The forged-steel crankshaft provides the necessary stamina. Twin balance shafts located in the oil sump cancel second-order noise and vibration and a deep-skirt block is engineered for extra stiffness.

Fuel is delivered to the intake ports by an electronically controlled sequential injection system. Ignition coils are modular units positioned directly above the spark plugs. Shim-less bucket tappets require no maintenance. Light-weight pistons are coated with a special anti-friction compound and fitted with low-tension rings for improved gas mileage. Sintered powder-metal connecting rods and lighter full-floating wrist pins minimize the reciprocating weight.

Like the MZR 2.0L, the new 2.5L power plant features variable intake valve timing and a two-mode composite intake manifold. A 4-into-1 exhaust manifold improves cylinder scavenging and reduces the time necessary for the catalytic converter to warm to full operating temperature.