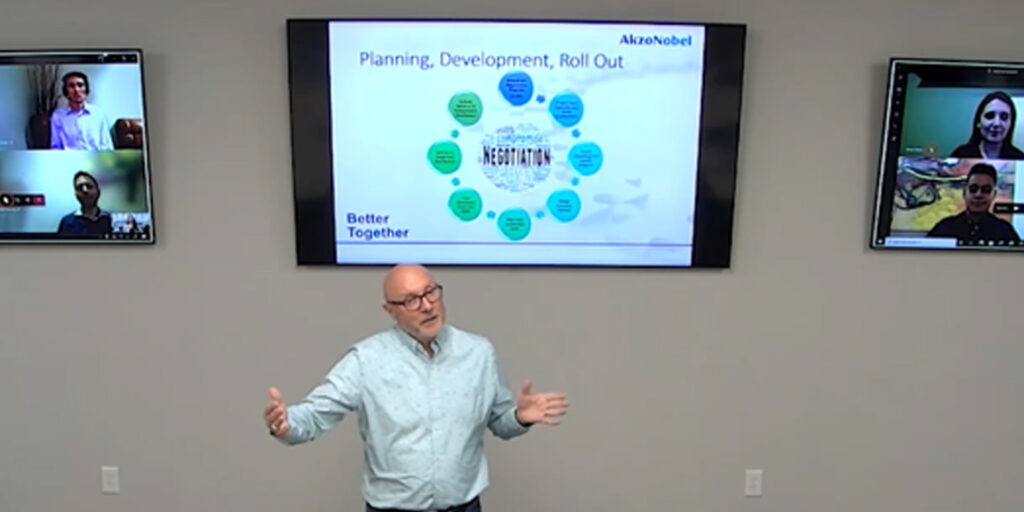

AkzoNobel has announced the grand opening of its new national meeting and instructional center complete with ultra-high-tech audio-visual equipment to help those virtually attending meetings or training feel like they’re right in the room.

The idea for this new, high-tech hybrid training center came from AkzoNobel’s Michael Kuntz, who is responsible for employee, distributor and end-user customer development within its Automotive & Specialty Coatings group, which is always looking for ways to meet the needs of more customers in increasingly effective ways.

“In any type of meeting or learning environment, we want to create an experience that’s meaningful, impactful and engaging – something that’s both memorable and allows for practical application for our attendees,” Kuntz explains. “We set out in very early 2020 to create a space where we could conduct an in-person course or meeting that is also an immersive, digital experience; and there’s nothing like the onset of a global pandemic to accelerate your timeline.”

Scouring the digital space for tools to make this virtual training dream a reality, Kuntz selected three ultra-high definition cameras with pan tilt zoom capability, giving a 360-degree view of the room to virtual attendees. The cameras are controlled remotely from a production board, providing a seamless and engaging visual experience to those attending virtually.

Further enveloping the virtual audience into the space, there is an in-ceiling audio ecosystem – an array of high-tech microphones – that are so crisp and clear that an instructor or attendee from any location in the room can begin speaking and be heard by the streaming audience, thus eliminating the need for individual microphones. This advanced audio is also helpful when those from the in-person audience speak or ask questions, allowing virtual attendees to hear every word.

“There is one other key element to this training environment that is really special,” adds Kuntz. “We now have 4K wireless cameras with wireless microphones available allowing us to go on location, say from classroom to spray booth, further enhancing the experience for those live streaming the course or training.”

The whole operation is orchestrated at a production station in the back of the room – much like the production of a television show. Each individual meeting or instructional session will have a production script specifying exactly how digital assets will be used. The production script is then uploaded to live stream production software, allowing AkzoNobel to seamlessly integrate video streams, video clips, still photos and presentations. Microphones are all connected to a hub and controlled from the production station by a common amplifier.

“Kudos to Michael and the entire team responsible for so quickly making this new training center a reality to better serve our customers right now and well into the future,” said Helmut Piotrasch, Sales Excellence and Commercial Operations manager – AkzoNobel Automotive & Specialty Coatings – Americas.